Wastewater treatment is an area where a lot of experts have carried out in-depth research. According to The United Nations World Water Development Report (WWDR), about 80% of wastewater is released into the water bodies without proper treatment on a global scale.

In the previous blog, I showed you some innovative ways to conserve water. Today we are going to dig deeper into the journey of wastewater through a wastewater treatment plant.

In the first section, let me introduce you to the wastewater treatment process.

Wastewater Treatment Process

The method of removing pollutants from wastewater or sewage and converting it into an effluent that can be added to the water cycle is known as wastewater treatment. In wastewater treatment plants, pollutants in wastewater are reduced to a degree that nature can accommodate.

Here’s a step-by-step guide to explain what happens at each point of the treatment process and how contaminants are neutralised or removed to help keep our rivers and streams safe.

Also check out some rainwater harvesting methods.

Wastewater Treatment Stages

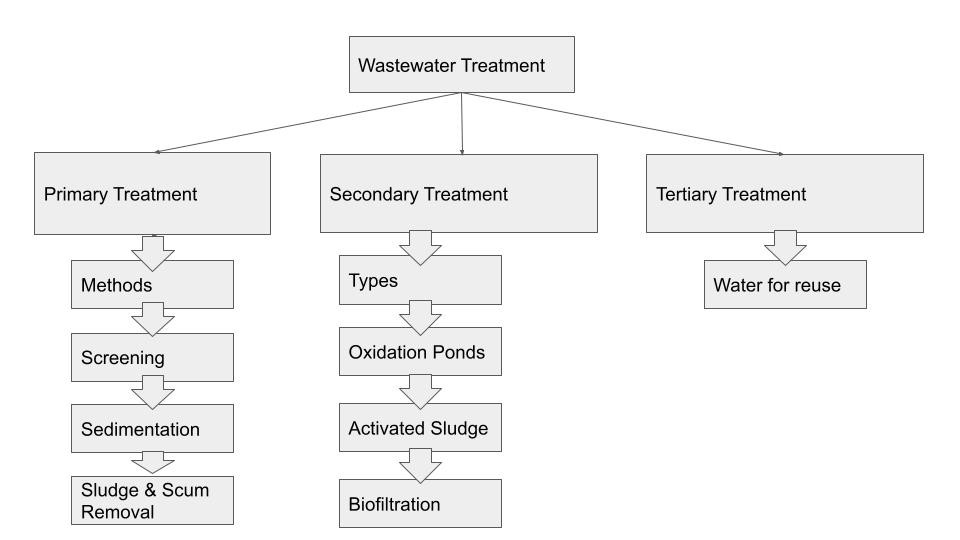

As shown in the diagram, the three main stages in the treatment of wastewater are:

- Primary Treatment

- Secondary Treatment

- Tertiary Treatment

Let’s analyse what happens in each of the stages in detail.

Primary Treatment of Wastewater

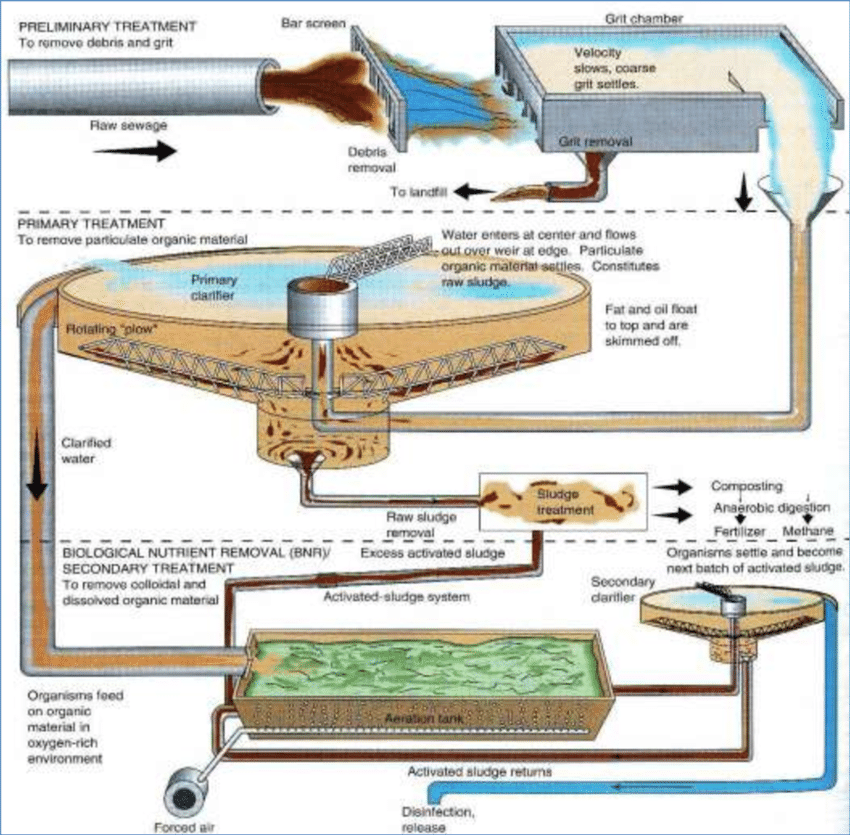

Wastewater reaching a treatment plant through pipes first undergoes primary treatment irrespective of its source. About 60% of the suspended solids are removed from the wastewater during primary treatment along with aeration or stirring in the water to put oxygen back. It includes the following steps:

1. Screening

- The majority of the floating materials are removed from the wastewater using screens of 10 mm openings and settling tanks.

- The floating materials include stone, rocks, sticks and even dead animals. Solid materials make up about a third of the wastewater.

- As a result, eliminating solid waste at the initial stage makes subsequent treatment procedures easier. Also, they may cause problems later in the treatment process if they are not removed.

- Solid waste is collected and disposed of in landfills after the screening process.

2. Sedimentation

- The sewage then flows through the grit trap or grit chamber which collects sand, cinders, and small stones at the bottom.

- The wastewater is then directed to sedimentation ponds, settling tanks, or clarifiers after the settled grit have been removed.

- Organic and inorganic matter, as well as suspended solids, are removed in this process.

- The suspended particles begin to fall to the bottom and form a solid mass known as sludge.

3. Sludge Removal

- In the sedimentation tanks, sludge (the organic solid component of the sewage) settles out of the wastewater.

- Mechanical scrapers in the tank’s base continuously move accumulated sludge to a hopper, where it is pumped to sludge treatment facilities.

- The thickening step removes some of the water before the sludge is processed in digesters.

4. Scum Removal

- Lighter materials rise to the surface as sludge settles to the bottom of the sedimentation tanks.

- Grease, oils, plastics, and soap are among the ‘scum.’

- Scum is skimmed off the surface of the wastewater by slow-moving rakes.

- Scum is thickened before being poured into the digesters with the sludge.

Around 90% of suspended solids, 55% of faecal coliforms, and 50% of biological oxygen demand are removed during the primary treatment process. The waste must be subjected to secondary treatment in order to be completely free of toxic substances. Let’s see how to do that.

Secondary Treatment of Wastewater

- Secondary wastewater treatment is designed to significantly degrade the biological content of the waste by aerobic biological processes, and it operates at a deeper level than primary treatment.

- During secondary wastewater treatment, about 85% of the organic matter in sewage is eliminated.

- The method entails combining the wastewater with bacteria and oxygen at high pressures.

- Bacteria digest organic matter with the aid of oxygen.

Secondary wastewater treatment reduces common biodegradable pollutants to acceptable levels, allowing for cleaner release into the nearby water bodies. It is done in one of three ways:

1. Biofiltration

Sand filters, contact filters, and trickling filters are used in biofiltration to ensure that any excess sediment is extracted from the wastewater.

- A trickling filter consists of a bed of stones that is about 6 feet tall.

- Sewage coming out of the sedimentation tank is permitted to pass through this stone sheet.

- The bacteria congregate on these stones and begin to multiply and evolve until all of the organic matter in the sewage has been consumed.

- Following the process, the clean water is piped out and directed to another sedimentation tank.

2. Oxidation Ponds

- Oxidation ponds, also known as lagoons or stabilisation ponds, are large, shallow ponds that use the interaction of sunlight, bacteria, and algae to treat wastewater.

- Algae use the sun’s energy, as well as carbon dioxide and inorganic compounds released by bacteria in the water, to grow.

- During photosynthesis, algae release oxygen, which is needed by aerobic bacteria.

- Mechanical aerators are often used to provide even more oxygen, reducing the size of the pond needed.

- Dredging is needed to remove sludge deposits in the pond.

- Filtration or a combination of chemical treatment and settling will kill any residual algae in the pond effluent.

3. Activated Sludge Process

- The air and sludge are allowed to come into close contact with the bacteria during this process and then passed into the settling tank.

- The sewage from the settling tank is first sent to an aeration tank, where bacteria are added to the air and sludge.

- The entire setup is left alone for several hours, during which time the bacteria decompose the organic matter into toxic by-products.

- The sludge, which has been activated by billions of bacteria, is returned to the aeration tank to handle fresh sewage.

- The previously treated wastewater is pumped to the sedimentation tank, which filters out any bacteria.

We have seen the primary and secondary treatment of wastewater. Now it’s time to see what happens in the tertiary treatment of wastewater.

Tertiary Treatment of Wastewater

The aim of tertiary wastewater treatment is to improve the water’s quality to meet domestic and industrial standards, as well as to meet specific criteria for water discharge safety. It can be done by ion exchange, reverse osmosis, chemical precipitation, membrane filtration etc. In the case of municipally treated water, the tertiary treatment also includes the elimination of bacteria, ensuring that the water is safe to drink.

In some cases, quaternary treatment is also done. This stage deals with contamination levels of a few parts per million to billions of parts per billion, and it often includes oxidation or fine filtration.

Shall we wrap up?

Conclusion

Wastewater treatment refers to the purification of sewage from various sources and converting it into a reusable form. It involves mainly 3 stages namely primary, secondary and tertiary.

Primary treatment involves screening, sedimentation, sludge and scum removal. Secondary treatment deals with the removal of biological contaminants using oxidation ponds, trickling filters or activated sludge process. Finally, the Tertiary treatment converts water into a reusable form.

The management of wastewater is inextricably related to the availability of clean and adequate water sources. Far from being anything to discard or neglect, wastewater will play an important role in meeting the increasing water demand in rapidly expanding cities, improving energy production and industrial growth, and promoting sustainable agriculture.