Introduction

Non-destructive testing (NDT) has long been a cornerstone in ensuring the integrity and safety of structures, components, and materials across various industries. As technology advances, the integration of nanotechnology into NDT has opened up new frontiers, offering unprecedented levels of precision, sensitivity, and efficiency. This article provides an overview of the convergence of non-destructive testing and nanotechnology, exploring the innovative techniques, applications, and potential impact on diverse sectors.

Non-destructive Testing (NDT)

Non-destructive testing encompasses a range of techniques designed to evaluate the properties of materials without causing damage. These methods are crucial for identifying defects, assessing structural integrity, and ensuring the reliability of critical components. Traditional NDT methods include ultrasonic testing, radiography, magnetic particle testing, and eddy current testing. While these methods have proven effective, the marriage of NDT and nanotechnology is poised to revolutionize the field.

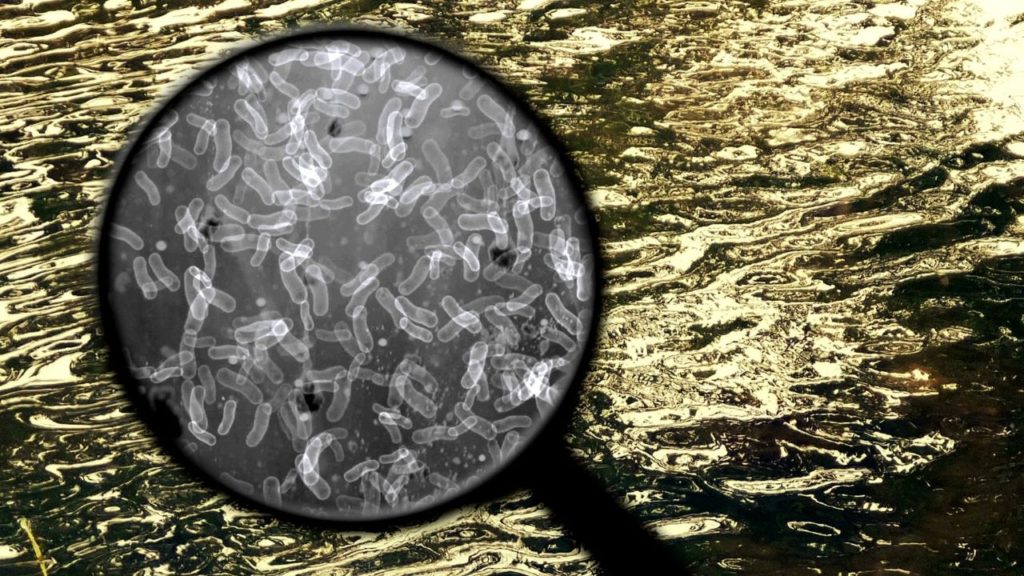

Nanotechnology in NDT

Nanotechnology involves manipulating materials at the nanoscale, typically at dimensions of less than 100 nanometers. When applied to NDT, nanotechnology brings a wealth of advantages, including enhanced sensitivity, improved resolution, and the ability to detect defects at a microscopic level. Here are key ways in which nanotechnology is making an impact in non-destructive testing.

Enhanced Imaging Resolution

Nanomaterials, such as nanoparticles and nanocomposites, enable the development of advanced imaging agents. These agents, when incorporated into NDT methods like radiography or magnetic resonance imaging, enhance resolution and provide detailed insights into the internal structure of materials.

Sensitivity Improvement

Nanoscale sensors and probes enhance the sensitivity of NDT techniques. For instance, nano sensors can be employed in ultrasonic testing to detect minute defects or irregularities that may go unnoticed with conventional sensors. This heightened sensitivity contributes to early defect detection and prevention.

Functional Nanomaterials

Functional nanomaterials, like carbon nanotubes or quantum dots, are employed to tailor specific properties for NDT applications. Carbon nanotubes, for example, can be used in sensors to improve conductivity and responsiveness, making them valuable for detecting flaws in materials.

Smart Coatings

Nanotechnology enables the development of smart coatings that respond to external stimuli, such as changes in temperature or stress. These coatings, when applied to surfaces, can reveal hidden defects or structural changes, providing real-time data during operation without disrupting the material’s integrity.

Applications of Nanotechnology in NDT

The incorporation of nanotechnology into non-destructive testing has resulted in a myriad of applications across diverse industries. Some notable areas where this synergy is making a significant impact include:

Aerospace Industry

In the aerospace sector, where the demand for lightweight yet robust materials is critical, nanotechnology aids in identifying defects at the nanoscale. This ensures the integrity of components like aircraft wings and fuselage, contributing to overall safety and efficiency.

Medical Imaging

In the field of medical imaging, the use of nanomaterials enhances the resolution of diagnostic tools. Nanoparticles can be employed as contrast agents in techniques like magnetic resonance imaging (MRI) or ultrasound, allowing for more accurate and detailed medical assessments.

Materials Science and Manufacturing

Nanotechnology plays a pivotal role in materials science and manufacturing, where the detection of microscopic defects is crucial. Whether assessing welds in construction materials or inspecting microelectronics in manufacturing processes, nanotechnology-driven NDT ensures the quality and reliability of products.

Oil and Gas Industry

In the oil and gas sector, nanotechnology aids in the inspection of pipelines and critical infrastructure. Nano sensors can detect corrosion or structural weaknesses in real-time, preventing potential disasters and optimizing maintenance schedules.

Challenges and Future Directions

While the integration of nanotechnology into NDT holds immense promise, there are challenges that researchers and industries must address. Ensuring the scalability and cost-effectiveness of nanotechnology-driven NDT methods, as well as addressing potential environmental and health concerns related to nanomaterials, are crucial aspects.

The future of NDT with nanotechnology is likely to witness further innovations, including the development of autonomous nanorobots for in-situ inspections and the application of artificial intelligence to analyze complex nanoscale data. As research progresses, the synergy between non-destructive testing and nanotechnology will continue to redefine the boundaries of material inspection and quality assurance.

Conclusion

The convergence of non-destructive testing and nanotechnology represents a paradigm shift in how we assess the integrity of materials and structures. Nanotechnology’s ability to operate at the molecular and atomic levels brings unprecedented precision and sensitivity to NDT methods, ensuring early defect detection and contributing to enhanced safety across industries. As research and development in this field advance, the innovative applications of nanotechnology in NDT are poised to reshape industry standards, making material inspection more reliable, efficient, and technologically sophisticated.