Camber in roads is the slope or angle built into the road surface, typically seen on curved or sloped sections of the road. This slope is designed to provide several benefits, including improved drainage, enhanced vehicle stability, and better driver visibility. The purpose of camber on roads is to ensure safe and comfortable driving conditions for motorists.

The slope can be positive, negative, or zero, depending on the specific requirements of the road and the expected traffic flow. The appropriate camber for a road depends on various factors, such as the type of road, its location, and the expected speed and volume of traffic. Proper design and construction of road camber can significantly improve road safety, reduce the risk of accidents, and increase the lifespan of the road surface.

- Types of Camber in roads

- Significance of road camber

- Advantages of Camber on Roads

- Recommended Values of Camber in Road For Different Types of Road surface by IRC:

- Disadvantages of excessive road camber

Types of Camber in roads

Camber in roads, or road camber, refers to the slope built into the road surface, typically seen on curved or sloped sections. The road’s camber is usually indicated by the ratio 1:n or as a percentage. Proper camber design and construction are crucial to improve road safety, reduce accidents, and ensure adequate drainage and vehicle stability.

Here’s a list of the types of camber used in road design and construction:

- Positive camber

- Negative camber

- Zero camber

- Composite camber

- Sloped or straight camber

- Two straight-line camber

- Barrel camber

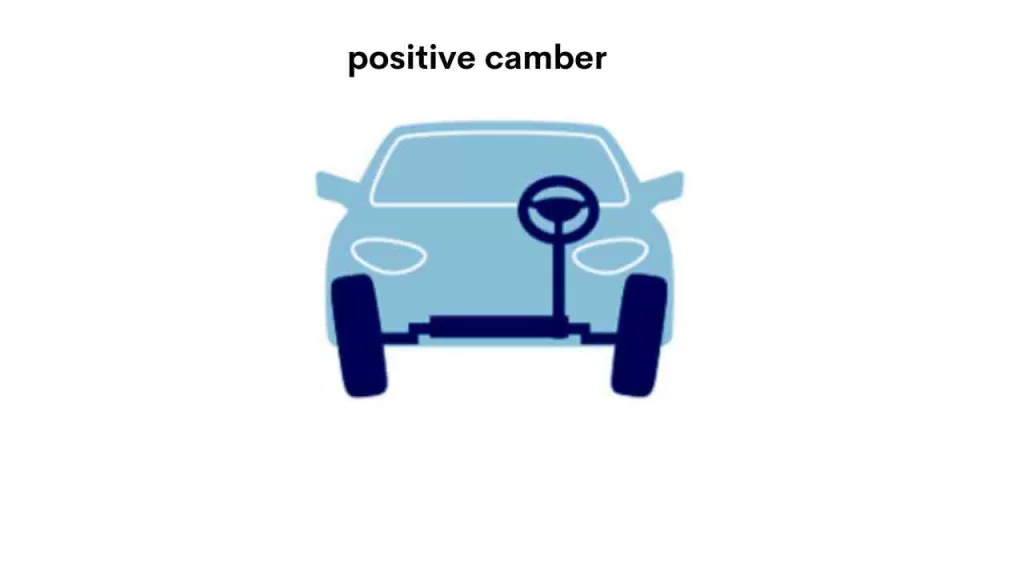

Positive camber in roads

Positive camber refers to the angle of a vehicle’s wheels where the top of the tire tilts outward from the centre of the vehicle. This can provide improved stability and handle in certain driving situations, such as high-speed cornering. However, excessive positive camber can lead to uneven tire wear and decreased handling performance.

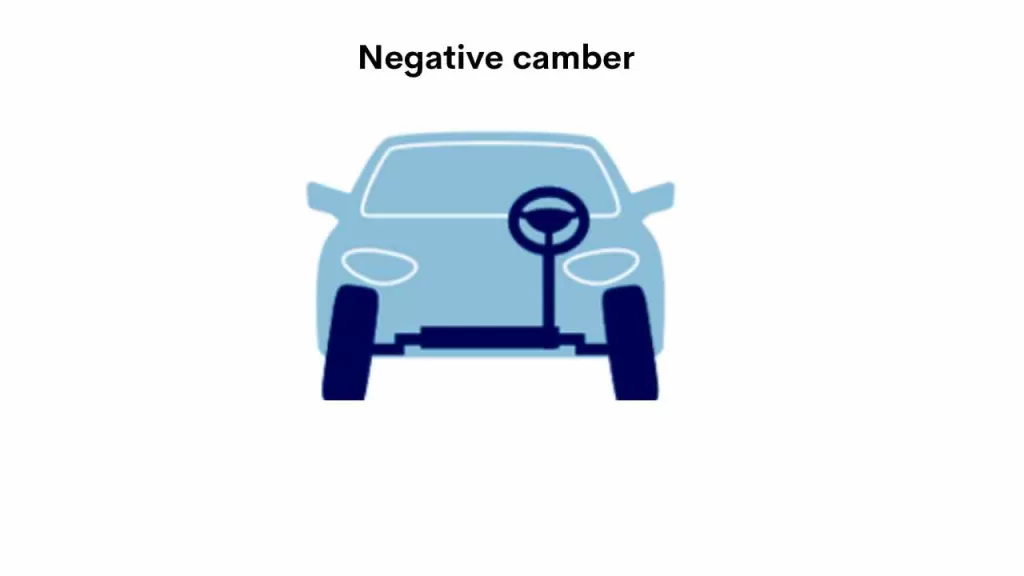

Negative camber in roads

Negative refers to the angle of a vehicle’s wheels where the top of the tire tilts inward towards the centre of the vehicle. This can provide improved grip and handling during cornering, as the tire maintains more contact with the road. However, excessive negative camber can lead to uneven tire wear and reduced straight-line stability.

Zero camber

Zero camber refers to the angle of a vehicle’s wheels where the tire is perpendicular to the ground and the wheel is vertical. This is considered the ideal angle for tire wear and handling, providing a balance between straight-line stability and cornering grip. Many production vehicles are designed with zero camber for optimal performance and safety.

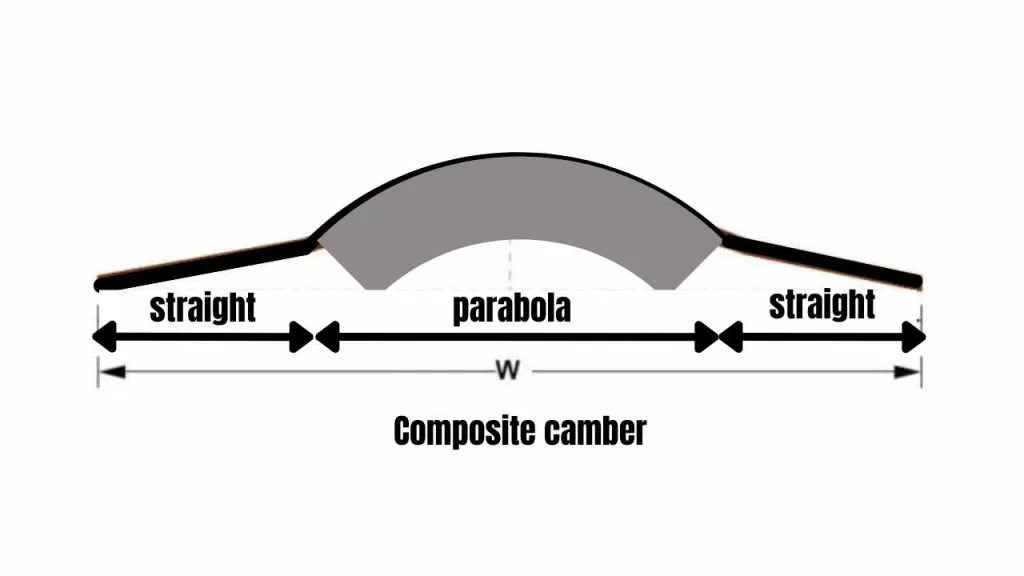

Composite camber

Composite camber refers to a combination of positive and negative camber on a vehicle’s wheels. In order to achieve optimal handling and performance in specific driving situations, one can adjust the angle of each wheel independently to create a custom setup. This allows for a personalized approach to handling and can be achieved through the use of composite camber. Composite camber is a technique commonly utilized in high-performance vehicles and motorsports to attain maximum grip and control.

Sloped camber/straight camber

Sloped camber refers to a wheel angle where the tire leans towards the inside or outside of the vehicle, creating a slope. Straight camber refers to a wheel angle where the tire is vertical and perpendicular to the ground. Sloped camber is often used in motorsports to improve cornering performance, while straight camber is more common in street vehicles for better tire wear and handling.

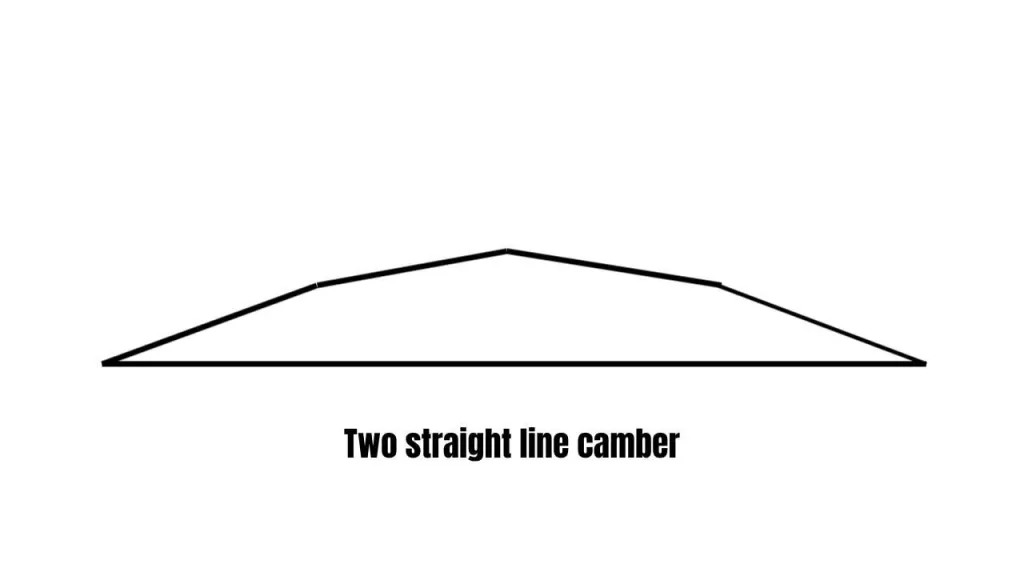

Two straight-line camber

Two straight-line camber refers to a setup where the camber angle is set to zero for both front and rear wheels. This provides a balanced setup that promotes even tire wear and stable handling. “People commonly use two straight-line camber in street vehicles, SUVs, and pickup trucks, prioritizing comfort, safety, and longevity over high-speed cornering performance.”

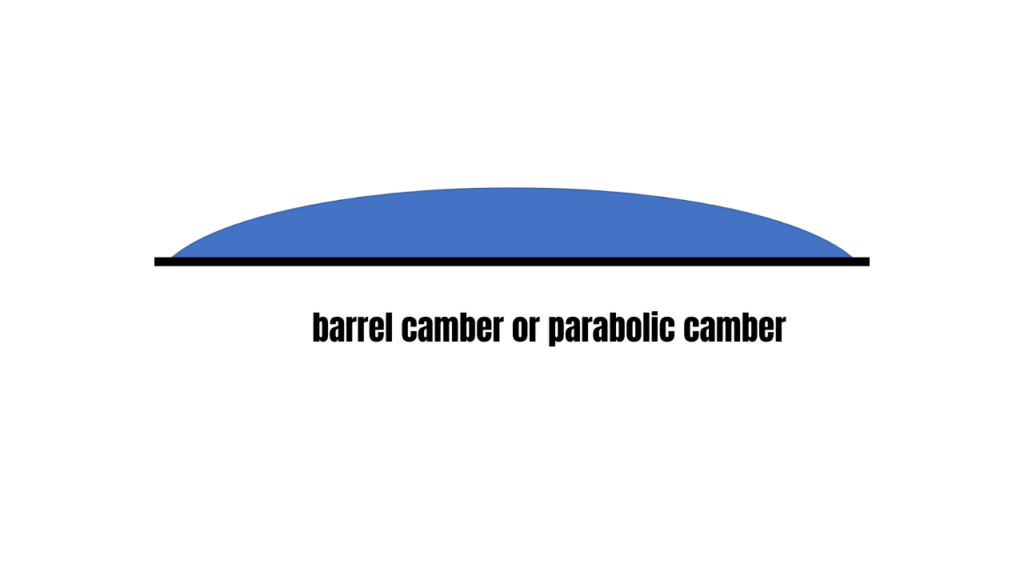

Barrel camber/Parabolic camber

“In drifting and racing applications, people commonly use barrel camber to promote tire grip . This in turn improves cornering performance by adjusting the camber angle and toe settings on each wheel independently. Barrel camber is a wheel angle where the center of the tire is lower than the edges, creating a barrel-like shape.”

Related posts from vincivilworld

Significance of road camber

Road engineers provide camber to promote safe and efficient driving. They use positive camber on curves and turns to offer better stability and prevent vehicles from sliding off the road. On the other hand, they use negative camber on straight sections to enhance tire traction and lower the risk of hydroplaning in wet conditions.

Advantages of Camber on Roads

Camber provides several advantages for road safety and efficiency. “Moreover,” positive camber assists vehicles in remaining centered on the road while turning. This in turn results in decreased skidding and improved stability. Negative camber improves tire contact with the road on straight sections, increasing traction and reducing hydroplaning risk. Camber also helps to reduce tire wear by distributing the load evenly across the tire surface, promoting longer tire life. Overall, camber is a key design feature in road engineering. This helps to promote safe, efficient, and sustainable transportation for all.

Recommended Values of Camber in Road For Different Types of Road surface by IRC:

The Indian Road Congress (IRC) provides recommended values for camber in road design, based on the type of road surface. These values are as follows:

- Flexible Pavement on Earth Embankment

- Straight: 1.5%

- Crossfall: 2.5%

- Flexible Pavement on Soft Soil

- Straight: 2%

- Crossfall: 3.5%

- Rigid Pavement on Earth Embankment

- Straight: 2%

- Crossfall: 3%

- Rigid Pavement on Soft Soil

- Straight: 2.5%

- Crossfall: 4%

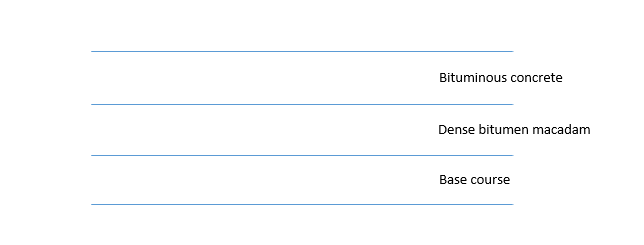

- Bituminous Wearing Course

- Straight: 1.5%

- Crossfall: 2.5%

“These values provide general guidance only and depend on local conditions, traffic volume, and other factors. It is important to note that.”

Disadvantages of excessive road camber

Providing excessive road camber height can have several disadvantages. These include:

- Uneven tyre wear: Excessive camber height can cause the tire to wear unevenly, leading to reduced tire life and increased maintenance costs.

- Increased fuel consumption: High camber angles can increase rolling resistance and reduce fuel efficiency, leading to higher fuel consumption and greenhouse gas emissions.

- Reduced braking performance: Excessive camber can reduce the contact area between the tire and the road surface, reducing braking performance and increasing stopping distances.

- Reduced stability: High camber angles can reduce vehicle stability, especially at high speeds, making the vehicle more difficult to control and increasing the risk of accidents.

- Uncomfortable ride: Excessive camber can cause the vehicle to ride harshly, transmitting more shocks and vibrations to the occupants, leading to discomfort and fatigue during long journeys.