Types of bonds in brick masonry commonly used in construction are detailed in this article. The process of bonding bricks with mortar in between them is known as brick masonry. Bricks are arranged in a pattern to maintain their aesthetic appearance and strength. This article is about the various types of bonds in brick masonry walls.

Bricks are rectangular construction materials. Bricks are commonly used in the construction of walls, paving, and other structures. They are also inexpensive and simple to work with.

- Types of Brick masonry bonds – Features

- Types of Bonds in brick masonry

Types of Brick masonry bonds – Features

For all types of brick masonry bonds to be stable and of high quality, the following characteristics must be followed.

- Bricks should be uniform in size.

- The lap should be a minimum of 1/4 brick along the length of the wall and 1/2 brick across the thickness of the wall.

- Uniform lapping is to be maintained.

- Avoid using too many brickbats.

- For getting a uniform lap Length of the brick should be twice its width plus one joint.

- The centre line of the header and stretcher in the alternate courses should coincide with each other for the stable wall.

- Stretchers should be used in facing and a header should be used in hearing.

RELATED POSTS FROM VINCIVILWORLD

Types of Bonds in brick masonry

There are different types of brick masonry bonds. They are

- Stretcher Bond

- Header Bond

- English Bond

- Flemish Bond

- Raking bond

- Zigzag Bond

- Herring-Bone Bond

- Facing Bond

- Dutch Bond

- Diagonal Bond

- Rattrap bond

Let us have a look at the most commonly used types of bonds in brick masonry.

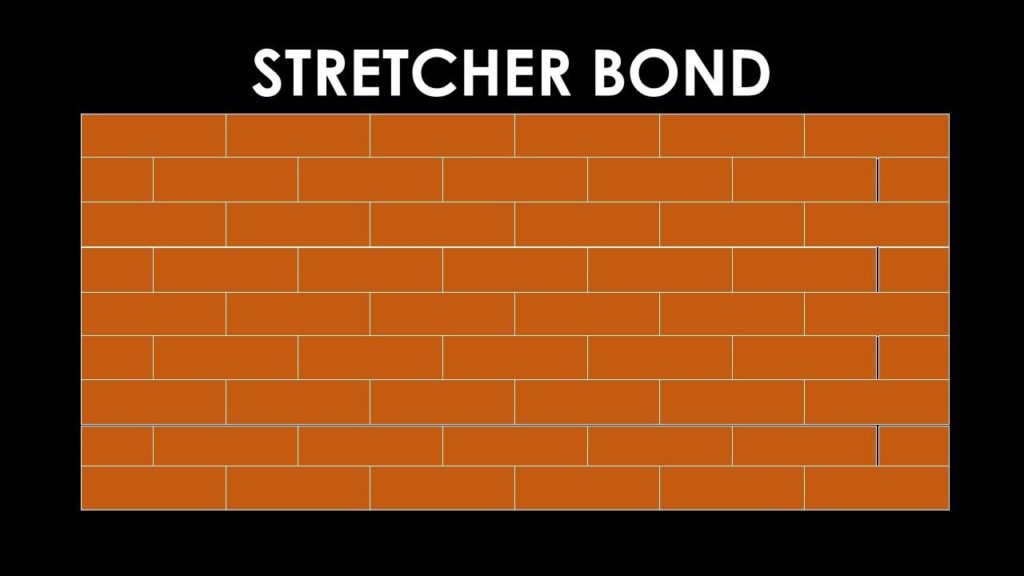

Stretcher bond – Types of Bonds in brick masonry

The stretcher is the brick’s lengthwise face or otherwise known as the brick’s longer, narrower face, as shown in the elevation below. Bricks are laid so that only their stretchers are visible, and they overlap halfway with the courses of bricks above and below. Accordingly, In this type of brick bond, we lay the bricks parallel to the longitudinal direction of the wall. In other words, bricks are laid as stretchers in this manner. It is also referred to as a walking bond or a running bond. Additionally, it is among the simplest and easiest brick bonds.

Limitations of Stretcher bonds

- Stretcher bonds with adjacent bricks, but they cannot be used to effectively bond with them in full-width thick brick walls.

- They are only suitable for one-half brick-thick walls, such as the construction of a half-brick-thick partition wall.

- Stretcher bond walls are not stable enough to stand alone over longer spans and heights.

- Stretcher bonds require supporting structures such as brick masonry columns at regular intervals.

Applications of stretcher bonds

Stretcher bonds are commonly used as the outer facing in steel or reinforced concrete-framed structures. These are also used as the outer facing of cavity walls. Other common applications for such walls include boundary walls and garden walls

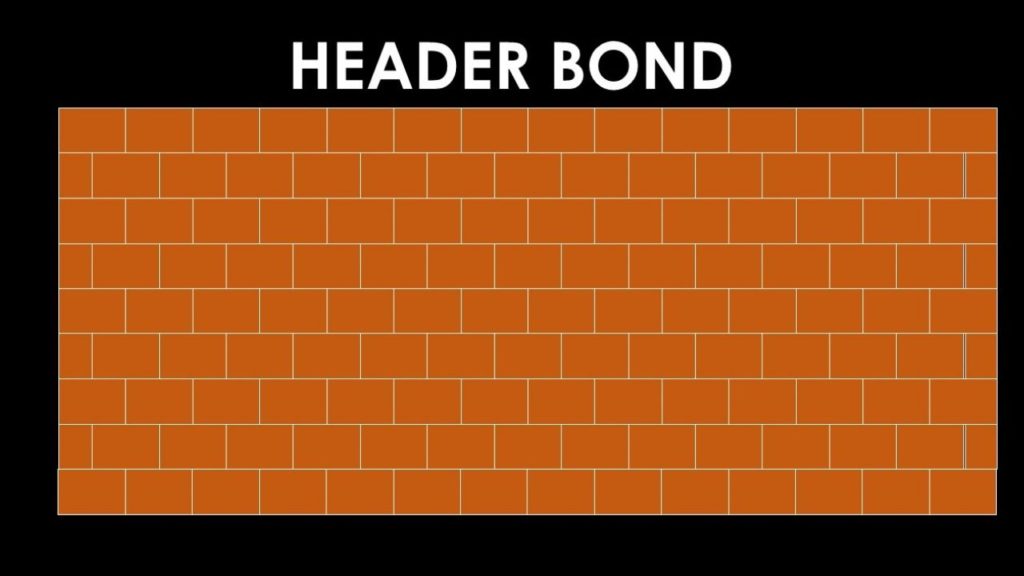

Header bond – Type of Bonds in brick masonry

Generally for header bond, the header is the brick’s widthwise face. In brick masonry, a header bond is a type of bond in which bricks are laid as headers on the faces. It’s also referred to as the Heading bond. The header is the brick’s shorter square face, measuring 9cm x 9cm. As a result, no skilled labour is required for the header bond’s construction. While stretcher bond is used for half brick thickness walls, header bond is used for full brick thickness walls that measure 18cm. Generally, in the case of header bonds, the overlap is kept equal to half the width of the brick. To achieve this, three-quarter brickbats are used in alternate courses as quoins.

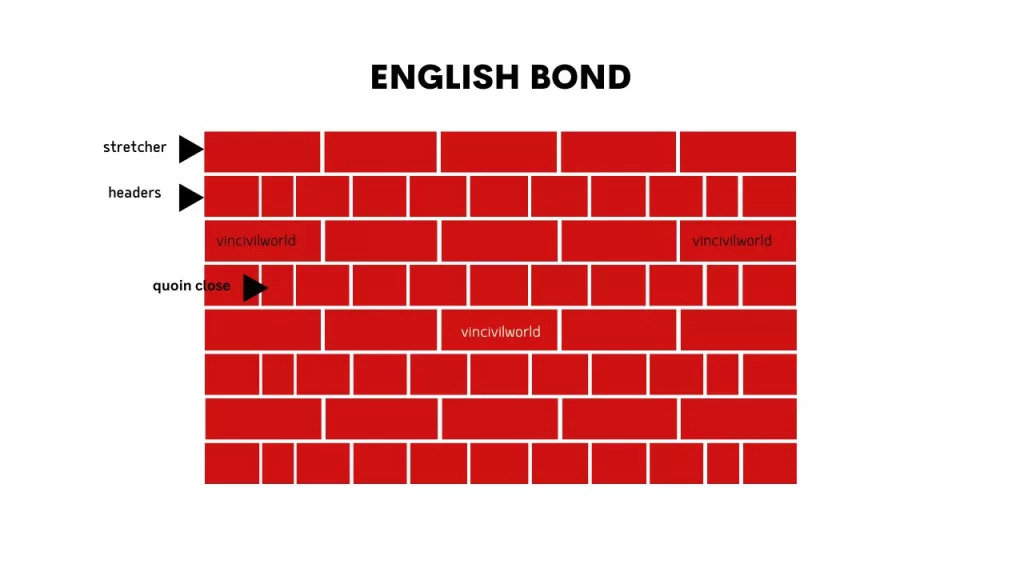

English Bond – Types of bonds in brick masonry

English bond uses alternative courses of stretcher and headers and is the most commonly used and the strongest bond in brick masonry. However, a quoin closer is used at the beginning and end of a wall after the first header to break the continuity of vertical joints. Mostly, a quoin close is a brick that has been cut lengthwise into two halves and is used at corners in brick walls. Similarly, each alternate header is centrally supported over a stretcher.

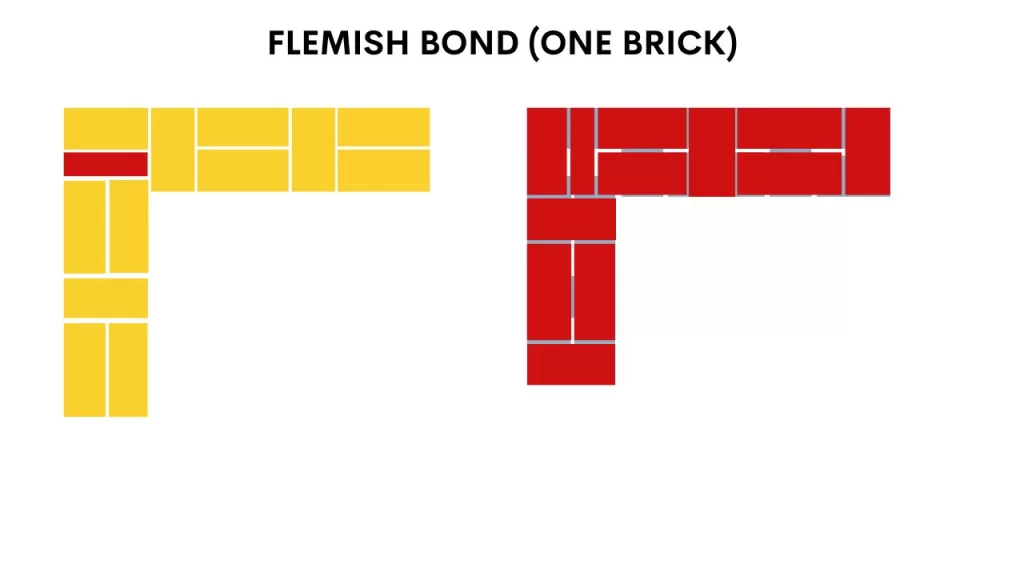

Flemish Bond

In Flemish bond, each course is a combination of header and stretcher. Accordingly, the header is supported centrally over the stretcher below it. Generally,closers are placed in alternate courses next to the quoin header to break vertical joints in successive layers. Flemish bond, also known as Dutch bond, is made by laying alternate headers and stretchers in a single course. The thickness of Flemish bond is minimum one full brick.The drawback of using Flemish bond is that it requires more skill to properly lay because all vertical mortar joints must be aligned vertically for best results. Closers are placed in alternate courses next to the quoin header to break vertical joints in successive There are two types of Flemish bond

- Double Flemish bond

- Single Flemish bond

Double flemish bond

The double flemish bond has the same appearance on both the front and back faces. As a result, this feature gives a better appearance than the English bond for all wall thicknesses.

Single Flemish Bond

The English bond serves as the backing for a single flemish bond, which also includes a double flemish bond on its facing. As a result, both the English and Flemish bonds’ strengths are utilised by the bond. Similarly ,this bond can be used to build walls up to one and a half brick thick. Howerver,high-quality, expensive bricks are used for the double-flemish bond facing. Cheap bricks in turn may be used for backing and hearting.

The appearance of the Flemish bond is good compared to the English bond. Hencer, flemish bond can be used for a more aesthetically pleasing appearance. However, If the walls must be plastered, English bond is the best choice.

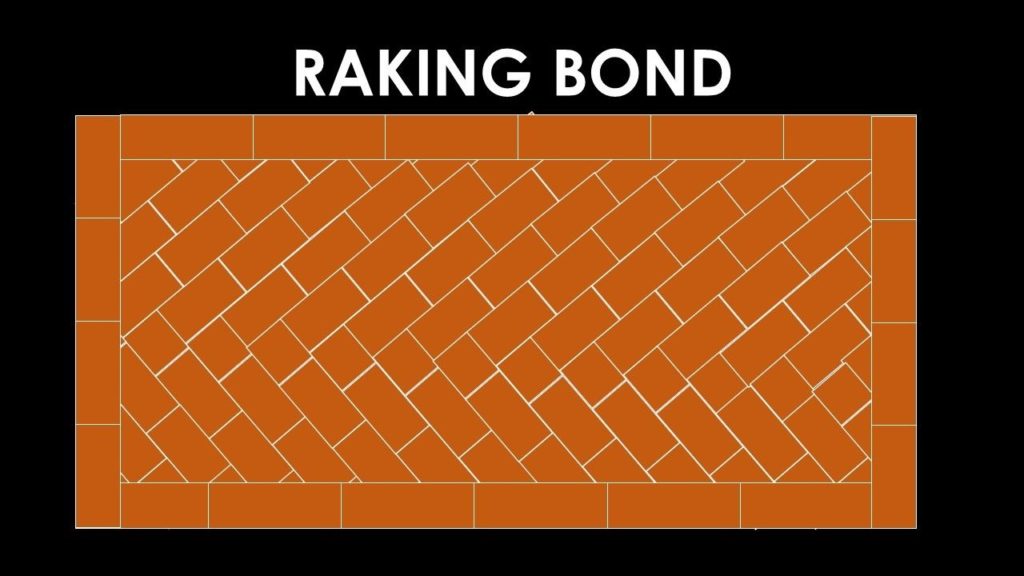

Raking bond

Raking bond is a type of brick bond in which the bricks are laid at angles. In this case, bricks are placed at an inclination to the direction of walls. Generally, it is commonly applicable for thick walls. Normally laid between two stretcher courses. There are two types of Raking bonds

- Diagonal bonds

- Herringbone bonds

Diagonal bonds

In diagonal bonds, bricks are laid inclined, the angle of inclination should be in such a way that there is a minimum breaking of bricks. These dioganal bonds are mostly applicable for walls of two to four brick thickness. Similarly, the triangular-shaped bricks are used at the corners.

Herringbone bonds

This type of bond is applicable in thick walls. The bricks are laid at an angle of 45 degrees from the centre in two directions. Mostly used in paving.

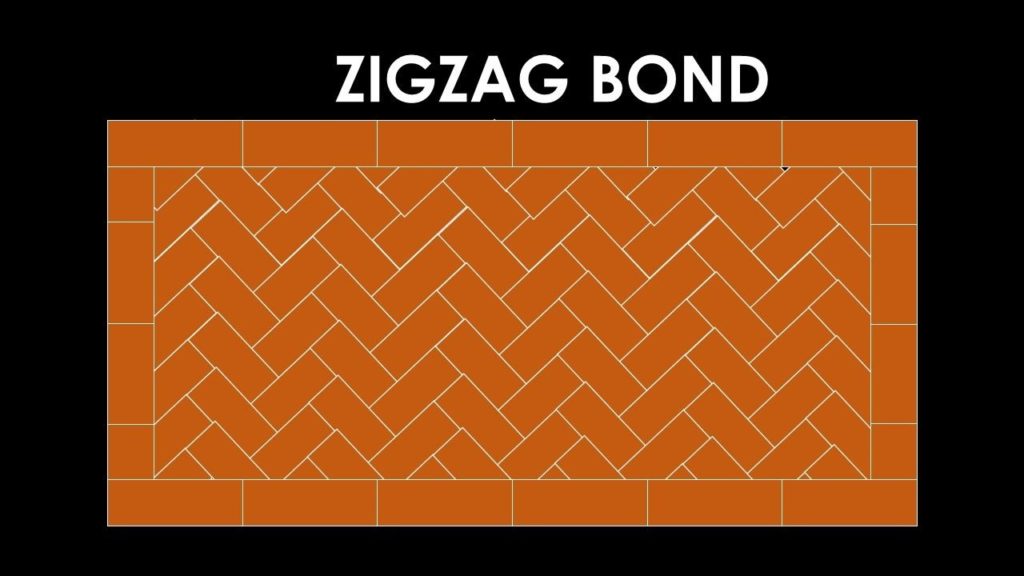

Zigzag Bond

In this type of bond, bricks are laid in a zig-zag manner. It is similar to the herringbone bond. Since Zig zag bond has an aesthetic appearance it is used in ornamental panels in brick flooring.

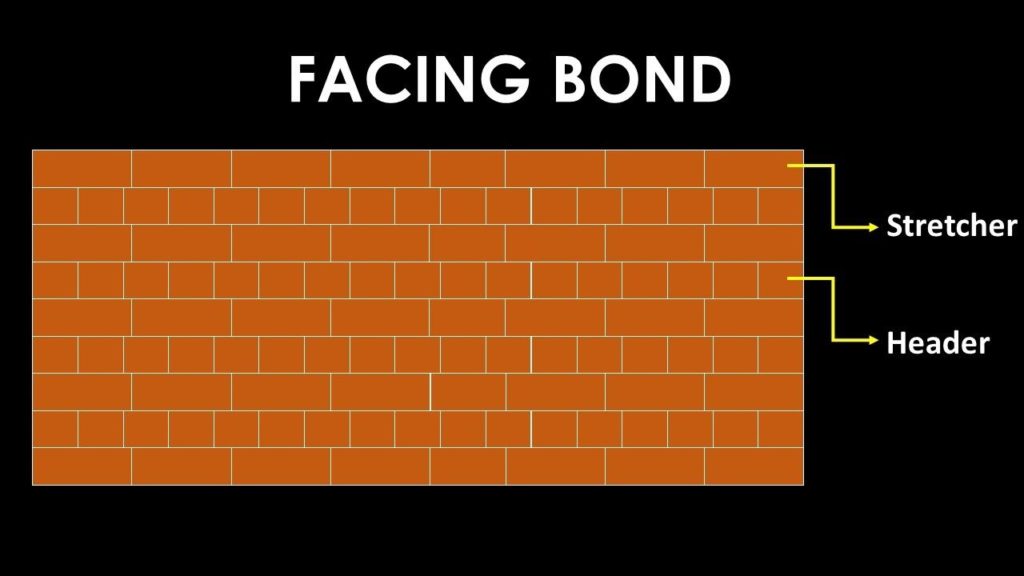

Facing Brick Bonds

In facing bond bricks are used of different thicknesses. It has an alternative course of stretcher and header. The load distribution is not uniform in this type of bonding. So it is not suitable for the construction of masonry walls.

Dutch Bond

It is a type of English bond. The specific pattern of laying bricks for building a wall is known as English and Dutch bonds. The primary distinction is that English Bond is a bond used in brickwork that consists of alternate courses of stretchers and headers. Dutch bond – made by alternating headers and stretchers in a single course.

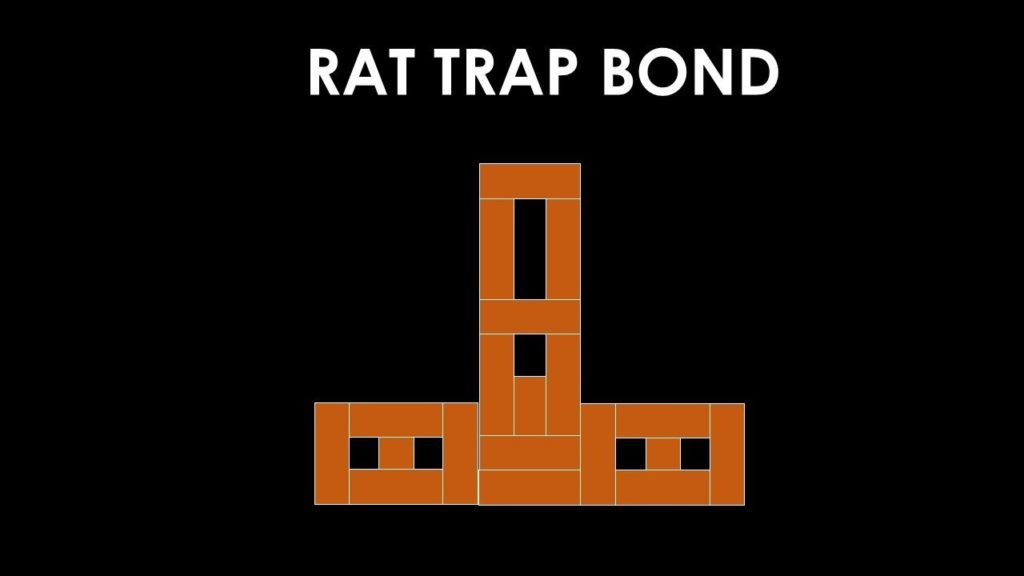

Rat trap bond

Another name of the rat trap bond is the Chinese bond. In this type of bond, the bricks are placed in such a way that a void is formed between them. These voids act as thermal insulators. Thus provides good thermal efficiency. It also reduces the number of bricks and the amount of mortar. Construction of rat trap bonds requires skilled labours.