Flyovers and bridges are essential transportation structures that enable the seamless movement of vehicles and pedestrians. While both serve similar purposes, flyovers navigate intersections efficiently as elevated roads, while bridges connect points over bodies of water or valleys. Their distinct features make them vital components of modern infrastructure. This article is about the features and advantages of Flyovers and bridges and the difference between flyovers and bridges.

- What is a flyover?

- What are the benefits of flyovers?

- Types of flyovers

- Classification of flyovers based on Materials

- What are bridges?

- Difference between Flyovers and Bridges

- Purpose

- Design of flyovers and bridges

- Location of flyovers and bridges

- Traffic Flow of flyovers and bridges

- Integration

- Environmental Factors

- Length and Span

What is a flyover?

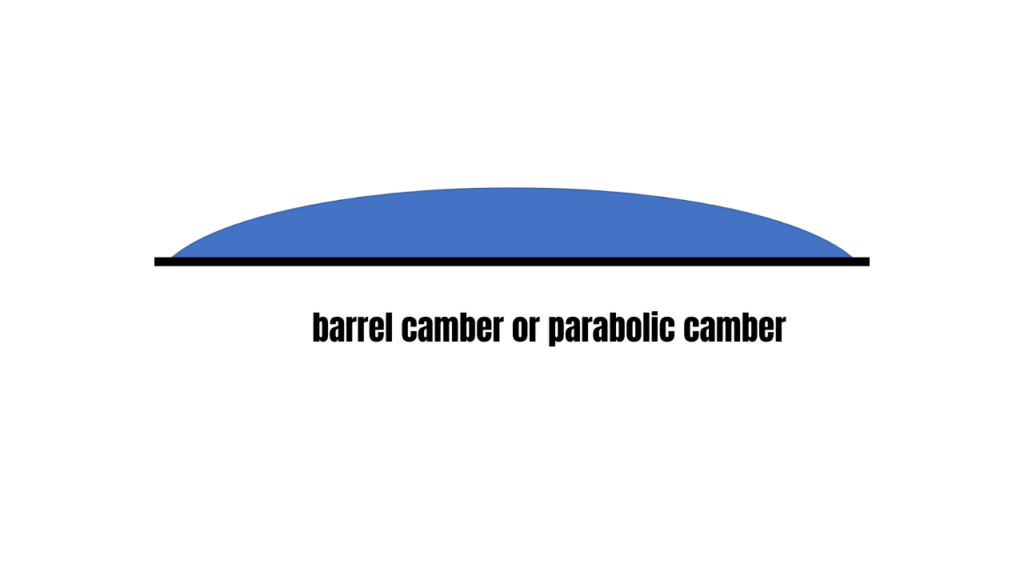

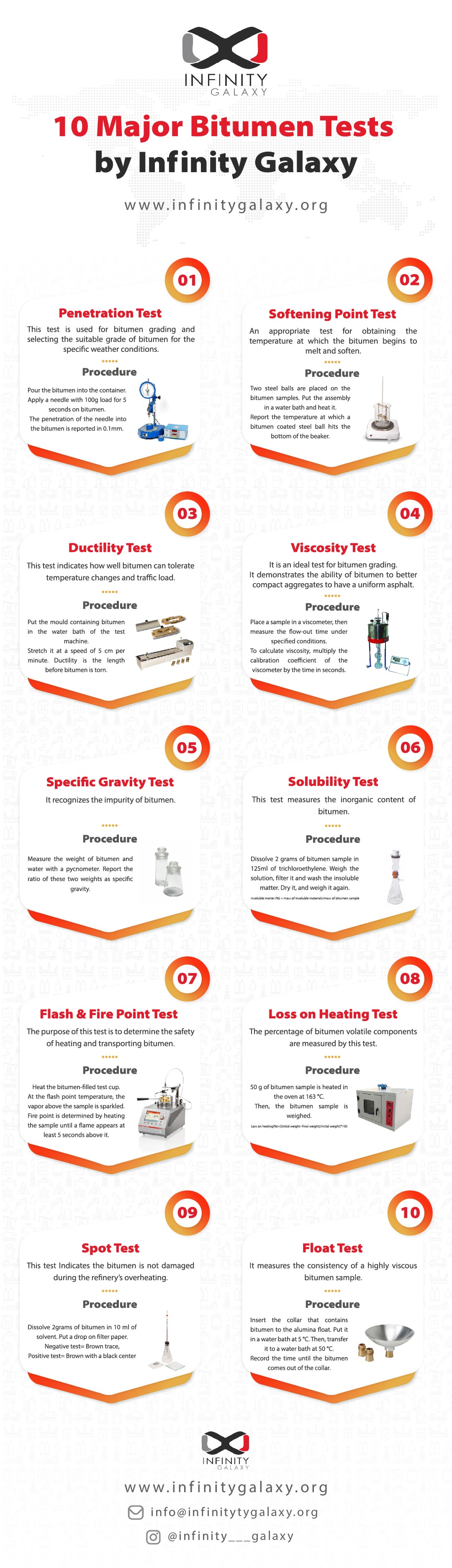

A flyover, also referred to as an overpass or an elevated roadway, is a transportation infrastructure that provides a dedicated elevated route for vehicles to traverse over obstacles such as intersections, congested areas, or other roads.”Designers create flyovers to enhance traffic flow, reduce congestion, and improve overall transportation efficiency.”

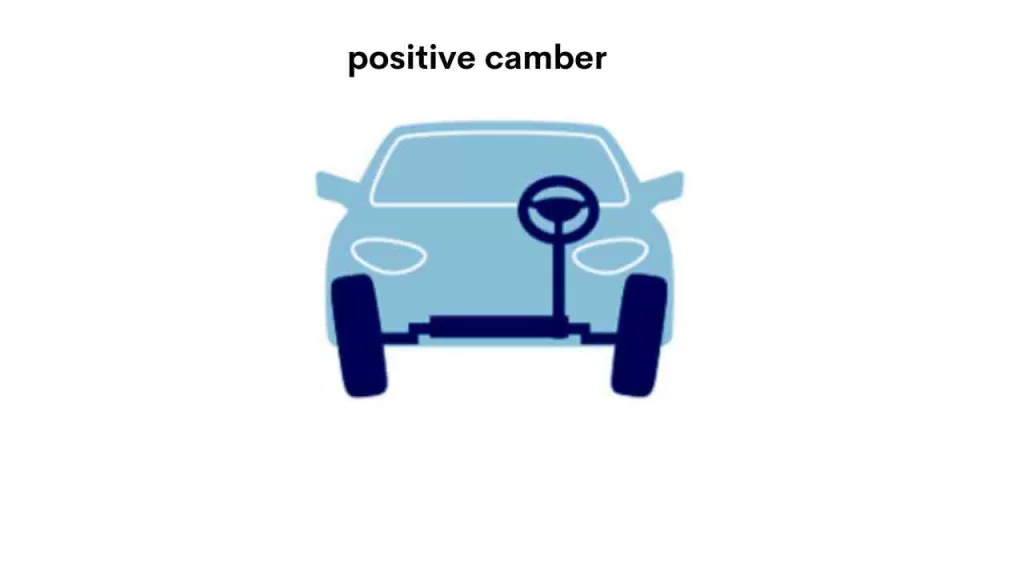

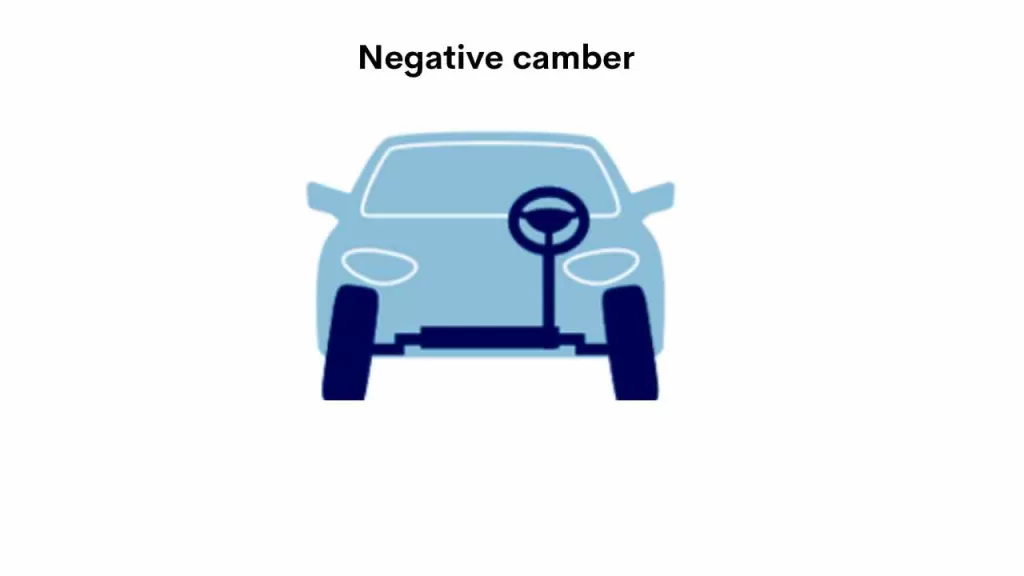

Constructors typically build flyovers above ground level, enabling vehicles to bypass busy intersections or intersections with heavy pedestrian traffic. Generally, by separating the flow of vehicles from crossroads and pedestrian crossings, flyovers minimize traffic conflicts and ensure uninterrupted movement. This in turn results in smoother traffic flow, reduced delays, and improved safety.

The construction of flyovers requires careful planning and engineering. Generally, builders often use reinforced concrete or steel girders to construct flyovers, providing structural support for vehicles and the ability to bear substantial loads. The design includes ramps or access points to enable smooth vehicle entry and exit onto the flyover, ensuring seamless integration with the current road network.

What are the benefits of flyovers?

The benefits of flyovers include:

- Improved traffic flow: Basically, Flyovers separate the flow of vehicles, reducing congestion and ensuring smoother traffic movement.

- Reduced travel time: By bypassing intersections or congested areas, flyovers enable faster and more efficient travel, saving time for commuters.

- Enhanced safety: Flyovers minimize the risk of accidents by eliminating conflict points between vehicles and pedestrians or conflicting traffic streams.

- Increased capacity: Flyovers can increase the capacity of road networks by providing additional lanes or routes for vehicles.

- Better fuel efficiency: Reduced congestion and smoother traffic flow on flyovers contribute to improved fuel efficiency and reduced emissions.

- Enhanced connectivity: Flyovers connect different parts of a road network, improving accessibility and connectivity between areas.

- Improved urban aesthetics: Well-designed flyovers with landscaping, architectural features, and decorative elements can enhance the visual appeal of urban landscapes.

- Economic benefits: Efficient traffic flow facilitated by flyovers can boost economic productivity by reducing transportation costs and improving logistics.

- Minimized environmental impact: Generally, flyovers can help reduce air pollution and noise pollution by minimizing congestion and idling time at intersections.

- Improved emergency response: Flyovers provide unimpeded routes for emergency vehicles, enabling quicker response times during emergencies or disasters.

Types of flyovers

Flyovers are classified based on the following factors

a) Classification based on the formation

b) Classification based on materials

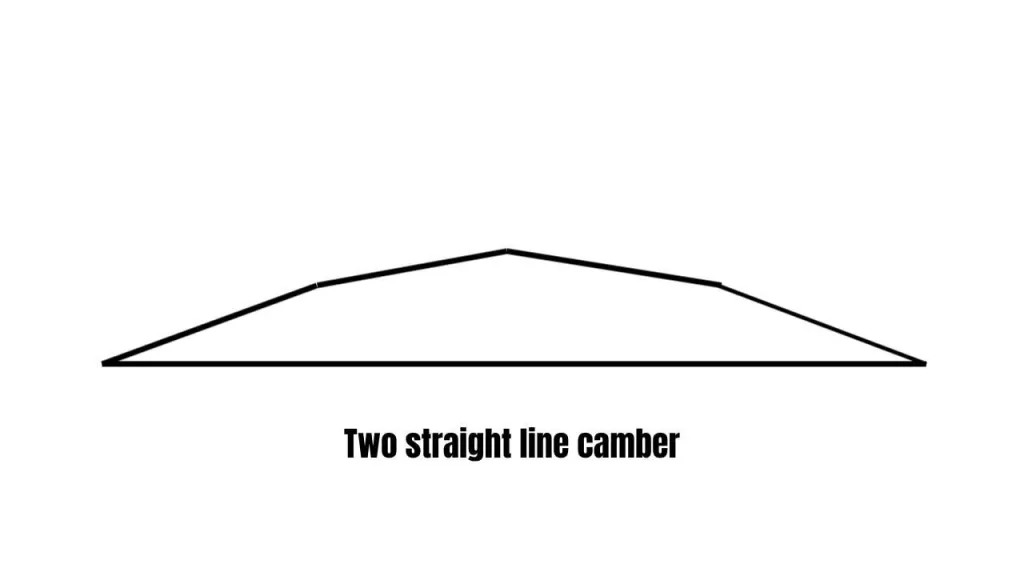

- Straight Flyovers: Follow a straight-line trajectory, providing a direct route over obstacles.

- Curved Flyovers: Incorporate curves or bends in their design, accommodating specific road alignments or geographical constraints.

- T-Junction Flyovers: Connect perpendicular roads at a T-junction, allowing for uninterrupted traffic flow in multiple directions.

- Cloverleaf Flyovers: Form a circular or cloverleaf-shaped interchange, facilitating smooth merging and diverging movements between roads.

- Diamond Flyovers: Feature a diamond-shaped interchange, allowing for efficient access and exits from multiple directions.

- Multi-Level Flyovers: Comprise multiple layers or levels, providing complex interchanges with ramps and access points for different roads.

- U-Turn Flyovers: Enable U-turns or reverse movements, allowing vehicles to change direction without disrupting traffic flow.

Classification of flyovers based on Materials

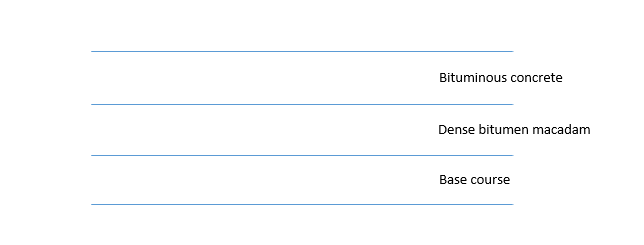

- Prestressed Concrete Flyovers: Constructed using precast prestressed concrete segments that provide strength and durability.

- Steel Flyovers: Built using steel girders, offering flexibility in design and allowing for longer spans.

- Reinforced Concrete Flyovers: Constructed using reinforced concrete beams or slabs, offering a balance between cost, strength, and ease of construction.

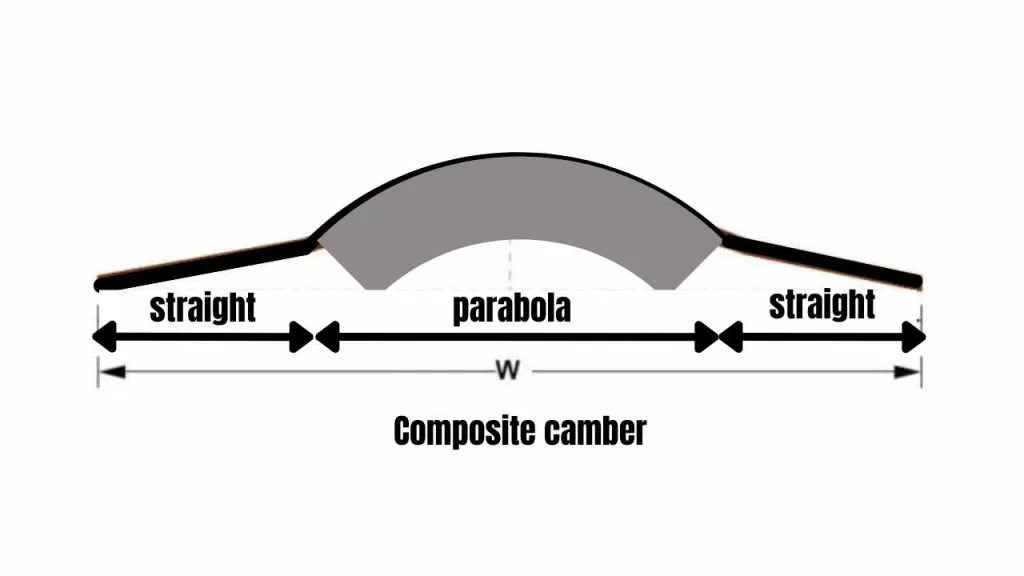

- Composite Flyovers: Combination of steel and concrete elements, leveraging the advantages of both materials for optimal structural performance.

- Cable-Stayed Flyovers: Supported by cables attached to tall towers, offering an elegant and efficient structural solution for longer spans.

- Box Girder Flyovers: Consists of hollow box-shaped beams, providing strength, rigidity, and resistance against bending and torsion forces.

- Extradosed Flyovers: Hybrid of cable-stayed and prestressed concrete flyovers featuring shorter towers and fewer cables while maintaining structural integrity.

What are bridges?

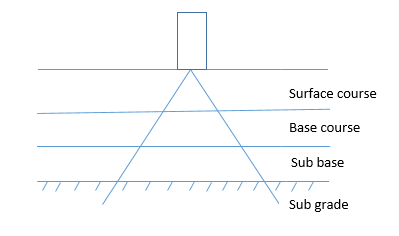

Engineers design bridges to connect two points over a body of water, a valley, or any physical obstacle. They typically comprise abutments, piers, and a deck or roadway for transportation. The construction of bridges involves using diverse materials like concrete, steel, or wood, which depend on factors such as span length and the required load capacity. However, They serve as crucial transportation links, facilitating the passage of vehicles, pedestrians, and sometimes, even trains. Bridges provide essential connectivity, improve accessibility, promote trade, and enable social and economic development by overcoming natural barriers and creating efficient transportation routes.

Difference between Flyovers and Bridges

Here are the key differences between flyovers and bridges

Purpose

| Bridges | Flyover |

| Bridges are primarily built to connect two points over a body of water, a valley, or any physical obstacle. | Flyovers are constructed to navigate intersections, congested areas, or other roads efficiently, providing an elevated route for vehicles. |

Design of flyovers and bridges

| Bridge | Flyover |

| Bridges are typically designed with piers or support that span across the obstacle, supporting a deck or roadway. | Flyovers are designed as elevated roadways, often supported by columns or piers, allowing vehicles to bypass intersections or congested areas. |

Location of flyovers and bridges

| Bridge | Flyover |

| Bridges are commonly found over bodies of water, such as rivers, lakes, or seas, or in areas with significant topographical variations like valleys or canyons. | Flyovers are usually constructed in urban areas with heavy traffic, where they can provide efficient bypasses for intersections or congested road segments. |

Traffic Flow of flyovers and bridges

| Bridge | Flyover |

| Bridges accommodate two-way traffic, allowing vehicles to travel in both directions. | Flyovers typically facilitate one-way traffic flow, with separate lanes or ramps for entering and exiting. |

Integration

| Bridge | Flyover |

| Bridges are integrated into the existing road network, connecting two points and providing a continuous route. | Flyovers are designed to integrate with existing roads, providing seamless connectivity by allowing vehicles to enter and exit at designated access points. |

Environmental Factors

| Bridge | Flyover |

| Bridges often need to consider factors like water flow, tidal forces, or seismic activity, depending on their location. | Flyovers focus on addressing traffic congestion and improving transportation efficiency, with less consideration for natural elements. |

Length and Span

| Bridge | Flyover |

| Bridges can vary in length and span depending on the distance they need to cover, ranging from short spans to long suspension or cable-stayed bridges. | Flyovers are generally shorter in length compared to bridges, spanning a specific area such as an intersection or congested road segment. |

Understanding these distinctions can help in determining the appropriate infrastructure solution based on the specific transportation needs and challenges of a given location.