Remote Sensing has been leveraged for various applications in various fields. We will see the definition, components & applications in civil engineering in this blog.

First let’s find out the definition of remote sensing.

What is remote sensing?

Remote sensing (RS) is the technology of acquiring information about the Earth’s surface without actually being in contact with it.

This is done by sensing and recording reflected or emitted energy and processing, analyzing, and applying that information.

I showed you the remote sensing definition.

We will find out the different components of RS now.

Remote sensing components

7 components involved in RS are,

- Energy Source or illumination

- Radiation and the atmosphere

- Interaction with the target

- Recording of energy by the sensor

- Transmission, reception and processing

- Interpretation and analysis

- Applications

- Energy Source or Illumination (A)– The first requirement for remote sensing is to have an energy source which illuminates or provides electromagnetic energy to the target of interest.

2. Radiation and the Atmosphere (B)– As the energy travels from its source to the target, it will come in contact with and interact with the atmosphere it passes through. This interaction may take place a second time as the energy travels from the target to the sensor.

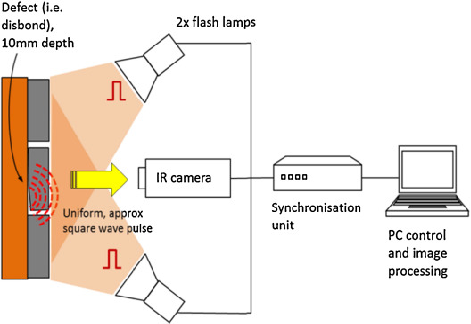

4. Recording of Energy by the Sensor (C) – After the energy has been scattered by, or emitted from the target, we require a sensor (remote – not in contact with the target) to collect and record the electromagnetic radiation.

5. Transmission, Reception, and Processing (D)- The energy recorded by the sensor has to be transmitted, often in electronic form, to a receiving and processing station where the data are processed into an image (hardcopy and/or digital).

6. Interpretation and Analysis (E)- The processed image is interpreted, visually and/or digitally or electronically, to extract information about the target which was illuminated.

7. Application (F)- The final element of the remote sensing process is achieved when we apply the information we have been able to extract from the imagery about the target in order to better understand it, reveal some new information, or assist in solving a particular problem

We will move to the principles of remote sensing next.

Remote sensing principles

Here we go with the principles.

- Electromagnetic energy reaching the earth’s surface from the Sun is reflected, transmitted or absorbed.

- Specific targets have an individual and characteristic manner of interacting with incident radiation that is described by the spectral response of that target.

- Electromagnetic_radiation (EMR) like radio waves, infrared (heat) waves make characteristic patterns as they travel through space

- Soils of differed types water with varying degrees of impurities, or vegetation of various species

The next section deals with the different types of remote sensors.

RS sensors types

There are mainly 2 types of sensors used in RS.

- Passive sensors- Passive system record energy reflected or emitted by a target illuminated by the sun. e.g. normal photography, most optical satellite sensors

2. Active sensors- Active system illuminates the target with energy and measure reflection. e.g. Radar sensors, Laser altimeters RADAR(Radio Detection and Ranging), LIDAR(Light Detection and Ranging)

I will walk you through the platforms for remote sensing next.

Remote sensing platforms

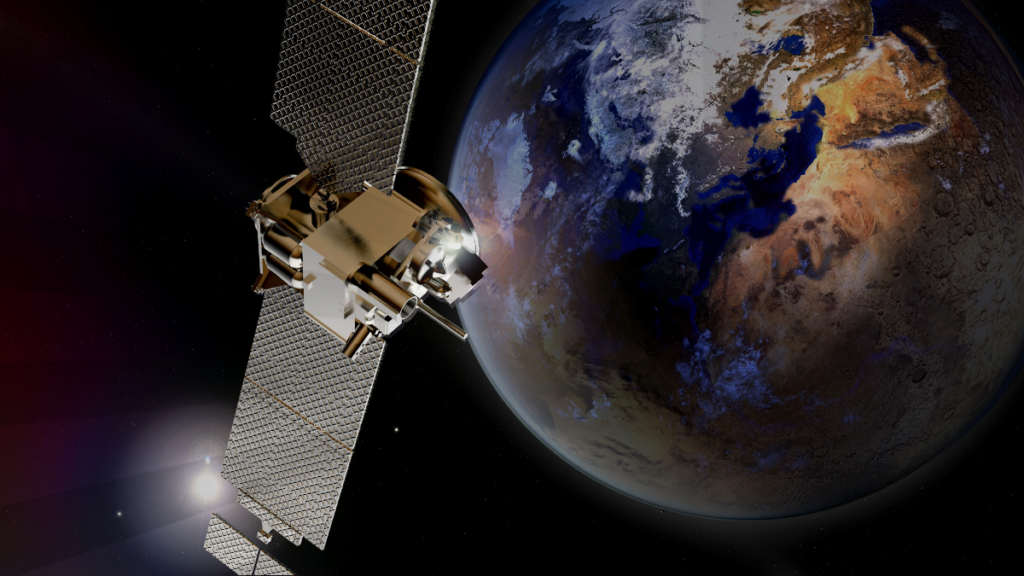

Platforms are used to house the sensors which obtain data for remote sensing purposes.

The distance between the target being imaged and the platform plays a large role in determining the detail of information obtained and the total area imaged by the sensor.

Platforms are-

- Ground-based

- Airborne eg. Aircraft, Drone

- Spaceborne eg. Satellite

Time to get into the last, but the most important section.

RS applications in civil engineering

- Site investigation

- Site investigations in general require topographic and geologic considerations.

- Remote sensing data permits such an assessment. In the case of dam site investigation, information on topography is essential.

- Geological consideration involves the different soil and rock types and physical properties.

- In selecting river-crossing sites for bridges and pipelines, an important consideration is the stability of slopes leading down to and up from the water crossing.

- Such slopes include riverbanks, terrace faces and valley wall.

- High spatial resolution satellite data can facilitate depth perception in the above-said investigations

2. Planning and design of highways

- Highways are part of the infrastructure that makes up the spinal cord of modern society.

- RS & GIS provides a valuable tool in the process of planning and design of highways.

- To obtain an optimum highway route alignment which is economical, suitable and compatible with the environment, various types of data have to consider simultaneously.

3. Groundwater location

- Knowledge of groundwater location is important for both water supply and pollution control analysis.

- Remote sensing plays a vital role in delineating potential areas of groundwater occurrence for detailed exploration.

- Thus, it reduces the cost and time involved in groundwater exploration. Potential groundwater areas cannot be seen as on satellite images directly

4. Landslide assessment

- Landslide is the result of a wide variety of processes which include geological, geomorphological and meteorological factors.

- The important terrain factors are lithology, structure, drainage, slope, land use, geomorphology and road network.

- A complete landslide hazard assessment requires an analysis of all these factors leading to instability in the region.

- The feature extraction of some of these factors can be done from the interpretation of RS using satellite images

That’s it about remote sensing. Let me your doubts in comments.

Happy learning!