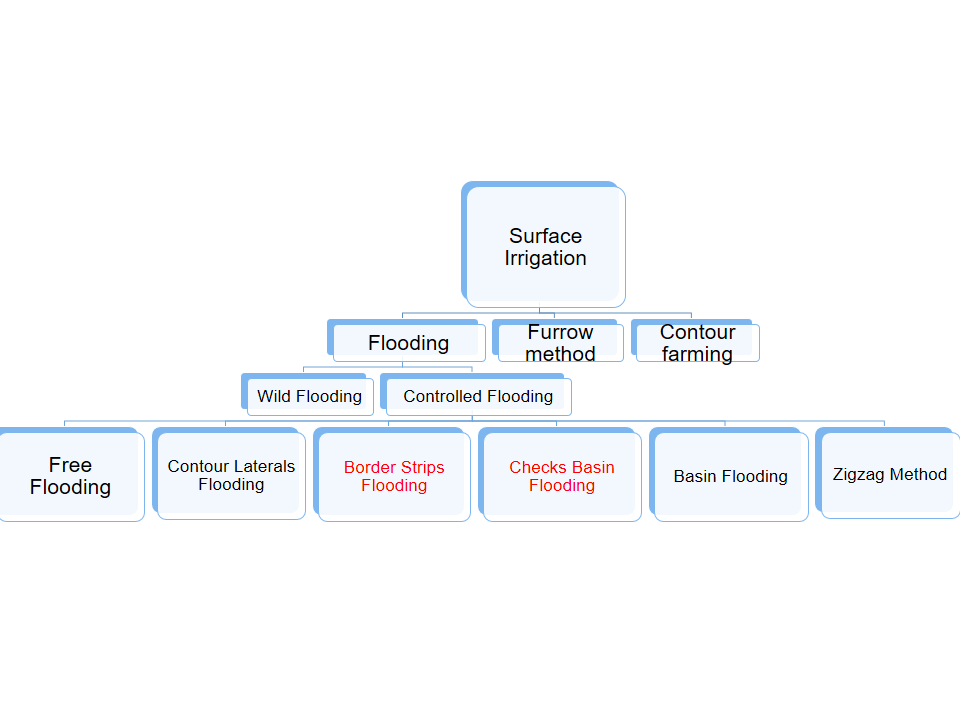

Types of flooding is an important topic in irrigation engineering, but they are usually classified based on the irrigation method rather than flooding itself. It’s mainly divided into three. Surface irrigation where water flows directly over the soil including basin flooding, furrow and border techniques.In subsurface irrigation water is delivered below the soil surface via tubes, minimizing evaporation. In case of sprinkler irrigation pipes and sprinklers are used to distribute water like rainfall.

In this blog, we will delve deep into the different types of controlled flooding in irrigation, exploring methods such as Free flooding, basin flooding, flooding by contour laterals, zigzag method of flooding, border strip flooding and check flooding are the 6 types of controlled flooding which is a subcategory of surface irrigation.

We will examine how these techniques manage water efficiently, their advantages, and their impact on agriculture and the environment.

What is Controlled Flooding Method of Irrigation

In controlled flooding, water is spread or flooded on a rather smooth flat land, without much control or prior preparation. This method is generally used in the inundation irrigation system in which water is forced to spread over vast tracts during the season of high streamflow.

It is a wasteful use of water and is practised largely where irrigation water is abundant and inexpensive.

Controlled flooding techniques in irrigation, including the flooding method of irrigation, optimize water use and minimize damage. Unlike traditional flooding irrigation, which can lead to inefficient water use, controlled flooding carefully manages water levels to enhance efficiency. Techniques such as free flooding, where water spreads broadly, and wild flooding, which lacks control, are contrasted with more precise methods like the check basin method. The check basin method uses barriers to contain and direct water, reducing runoff and erosion. Controlled flooding not only improves water distribution but also conserves resources and enhances crop yields. By managing water flow more effectively, these techniques address the challenges of traditional flooding, ensuring better agricultural outcomes and environmental sustainability.

Types of Controlled Flooding Irrigation

Controlled flooding irrigation includes several methods to manage water levels efficiently. These techniques aim to improve water distribution and reduce waste. let’s peep into the hierarchy of methods of controlled irrigation.

- Free Flooding irrigation/wild flooding irrigation

- Contour Lateral Flooding

- Border Strips Flooding irrigation

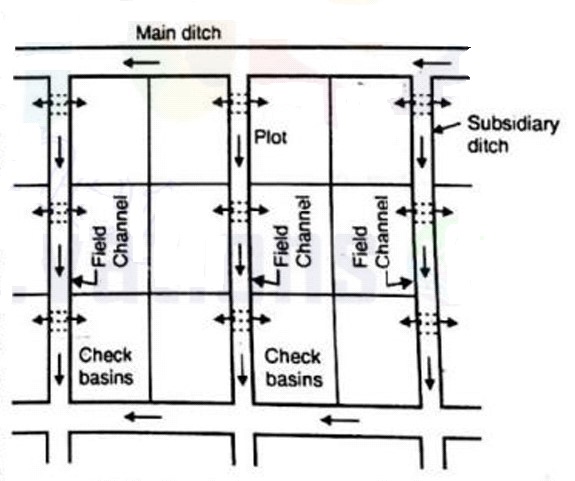

- Checks basin Flooding

- Basin Flooding

- Zigzag Method of Flooding

Free flooding or flooding from field channels

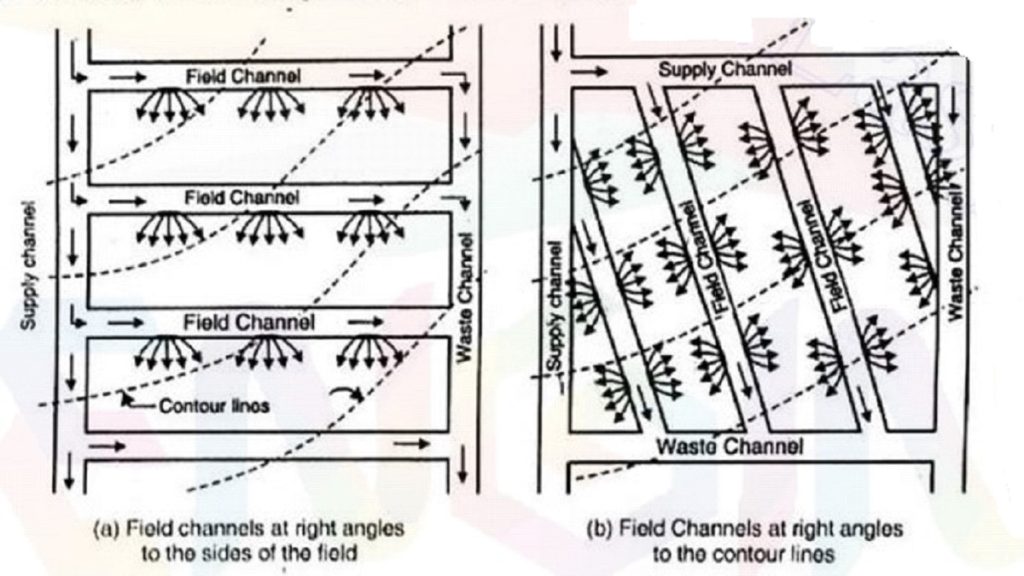

Free flooding method consists of dividing the entire land to be irrigated into small strips by a number of field channels known as laterals.

- These laterals may be either at right angles to the sides of the field, or at right angles to the contour lines as shown in figures.

- When the laterals are aligned at right angles to the sides of the lateral, irrigation is possible only to one side of the lateral. However, when the laterals are aligned at right angles to the contours, irrigation is done to both the sides of the lateral.

- The field channels receive water from the supply channel and discharge excess water in the waste channel.

- Water is applied to the strip of a land through feeding points provided at some interval along the laterals.

- This method of water application can be used both for flat lands as well as for relatively steep lands. The alignment and spacing of the laterals depends upon the type of soil and topography of land.

- If the slopes are steeper, the closer spacing of laterals is required. Similarly, closer spacing is required for relatively more permeable soils.

- For flat land and for relatively less pervious soils, the spacing of the laterals may be increased. Normally the spacing of the laterals may vary from 10 to 50 metres.

- However, the method is more suited for irrigation fields containing medium type soil and having slopes ranging from 1 in 100 to 1 in 300.

Let’s find out about the next method of controlled flooding.

Flooding by contour laterals

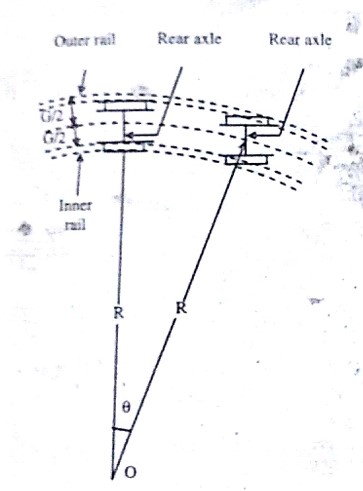

This is a special case of free flooding in which the field channels or laterals are aligned approximately along the contour lines.

This method is applicable to steeper terrain.

The field is cut by a relatively dense network of small contour laterals, the spacing of which depends upon the prominent grade of field between two adjacent ditches or laterals, the uniformity of slope and the soil type.

I have explained the details of border strip flooding and checks basin flooding in previous blogs. So, let’s move on to the next member.

ALSO READ: Rainwater Harvesting Methods: Everything You Need To Know

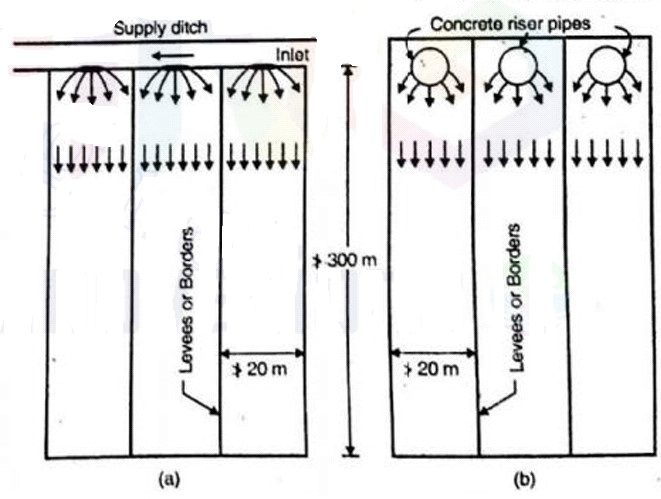

Border Strips Flooding irrigation

The border strip method, also known as border strip flooding irrigation, involves dividing a field into strips, typically 10 to 20 meters wide and 100 to 300 meters long, separated by low levees or borders. Water is directed from a supply ditch to the head of each strip, flowing down the slope in a controlled sheet, guided by the borders. The surface between the borders is kept level to ensure uniform coverage. Slopes vary from 0.2% to 0.8% along the strip, with cross slopes minimized to prevent uneven irrigation. This method is efficient for forage crops and requires minimal investment and labor. The length of each strip is adjusted based on soil type, infiltration rate, and irrigation stream size. For example, sandy soils typically use shorter strips, while clay soils may use longer ones.

Basin Flooding

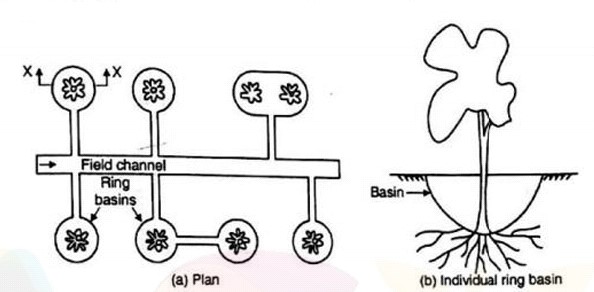

The ring basin flooding is a special form of check basin flooding adapted to orchards.

- Ring basins are formed for each tree; in some cases, one ring basin may be formed for two or more trees.

- Water is supplied to these basins through a supply ditch. In some cases, a number of ring basins are interconnected.

- Portable pipes or large hoses may also be used in place of ditches.

Last, but not the least let me explain about final method of controlled flooding.

Zigzag method of controlled flooding

It is special method of flooding where water takes circuitous route before reaching the dead end of each plot.

- The whole area is divided into a number of square or rectangular plots; each plot is then subdivided with the help of low bunds or levees.

- This method is suitable for relatively level plots. It is, however, highly unsuitable for farming operations with modern farm machinery.

That’s it about the methods of controlled flooding.

MUST-READ: Concept of green building- 4 comprehensive concepts easy read!

I hope you got a fair idea about free flooding, basin flooding, flooding by contour laterals and zigzag method of flooding.

Happy learning!