Soil nailing is a slope protection technique for supporting unstable natural slopes and over steeping of existing slopes. Soil nails are reinforcing passive elements drilled and grouted sub-horizontally in the ground. They are used to support excavations in soil, or soft and weathered rock and slope protection works.

Soil nails are steel bars inserted into soil to reinforce slopes, embankments, or excavation walls. By stabilizing the ground, soil nails prevent landslides and erosion. This cost-effective technique strengthens soil structures. It is widely used in geotechnical engineering for construction. Additionally, it is used for retaining walls and slope stabilization projects.

Soil nail walls are used as permanent earth-retaining structures in highway projects. They can also be constructed as temporary structures in roadway work when used as shoring of deep excavations.

- Components of soil nail and its function

- Applications of soil nails

- Feasibility of soil nail

- Advantages of soil nails over other retaining systems

- Key Takeaways

- Conclusion

Components of soil nail and its function

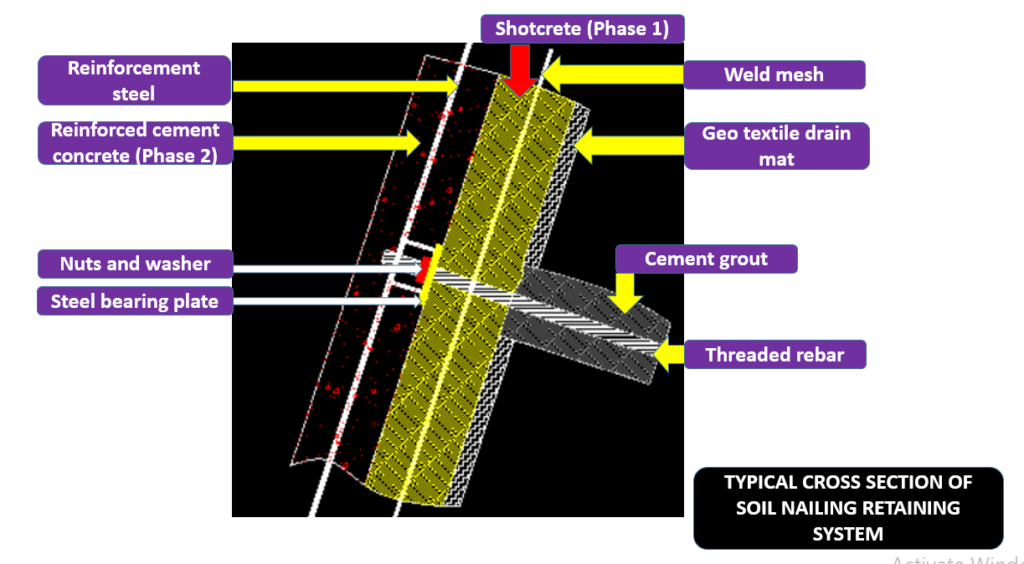

Components mainly constitutes installing passive reinforcement without any post tensioning in existing ground know as nails. Soil nails are later grouted if they are installed in drilled holes. Soil nails using solid bar drilling system do not need grouting. Hollow bars, such as the sacrificial hollow bar system, drill and grout simultaneously and also do not require additional grouting. Let us go in detail each and every component of soil nailing system.

Tendons

They are the ground reinforcing elements and are equivalent to steel bars. Tendons can handle tensile stress during the lateral movement and deformation of retained soil. They also manage external loads in the service stage, such as surcharge loads and traffic loads.

There are two methods of fixing soil nails or reinforcement bars.

a) Holes are drilled and pressure grouted with fully threaded bars embedded inside.

b) Using sacrificial drill bits where drilling and grouting will be done simultaneously and the sacrificial drill bit is converted to rebar.

Grout

Normal OPC cement mixed with water is used for grouting. The function of grout are

a) Transfers shear stress between the ground and tendons and

b) Corrosion protection for rebars.

Installation of facing

Soil nail construction is done from top to bottom. Every nail is installed with anchor plates or bearing plates.

First, a single row of soil nails is installed after excavating the surface. Excavate further and install the second layer of soil nails as per design. Once you reach a reasonable height, soil can free stand (1-2 meters) for at least 2-3 days. Then the next phase of the shotcreting process will start.

a) First face shotcrete on soil surface

A geotextile drain matting is placed over the soil. Then, it is followed by welded wire mesh as shown in the figure. Rebar stiffeners are sometimes provided to strengthen the shotcrete against punch shear forces. On completion of the first phase of shotcreting bearing plates with beveled washers are installed over the shotcrete surface.

b) Second phase of reinforced concrete

If required as per design, the first layer is covered with a second phase of reinforced concrete. This is shown in the figure. This concrete covers the nail head.

Applications of soil nails

Soil nails are one of the most economical and feasible tops to bottom constructed retaining walls system. They are technically feasible, fast, and reliable slope protection and earth retaining system. Soil nails offer a perfect cost-effective system for temporary retaining walls for deep excavations..

- High way cut excavation of hilly areas

- Road widening under an existing bridge end.

- Repair and reconstruction of existing retaining structures.

- Temporary or permanent deep excavations in urban areas.

Feasibility of soil nail

Before confirming the soil nail system please ensure the following parameters at the site.

- Soil should be able to free stand at a height of around 1-2 mtr. It must remain unsupported for a minimum of two days.

- All soil nails within a cross-section will be above the water table.

- If the soil nails are not located above the groundwater table, the groundwater should not negatively affect the excavation face. It should not harm the bond between the ground and the soil nail itself.

- They can be used for almost all types of soils. This includes stiff, sandy, or hard clay. They are also applicable to dense sand and gravel areas, as well as evenly weathered rocks.

- Avoid using soil nails in dry, poorly graded cohesion-less soils. Do not use them in soils with a high groundwater table, or in soils with cobbles and boulders. They are unsuitable for soft to very soft fine-grained soils, highly corrosive soils, and weathered rock with unfavourable weakness planes, etc.

Advantages of soil nails over other retaining systems

- Soils nails require very little workspace comparing with any other retaining systems.

- The operations are mostly light and silent and there is no disturbance to the traffic and people residing nearby.

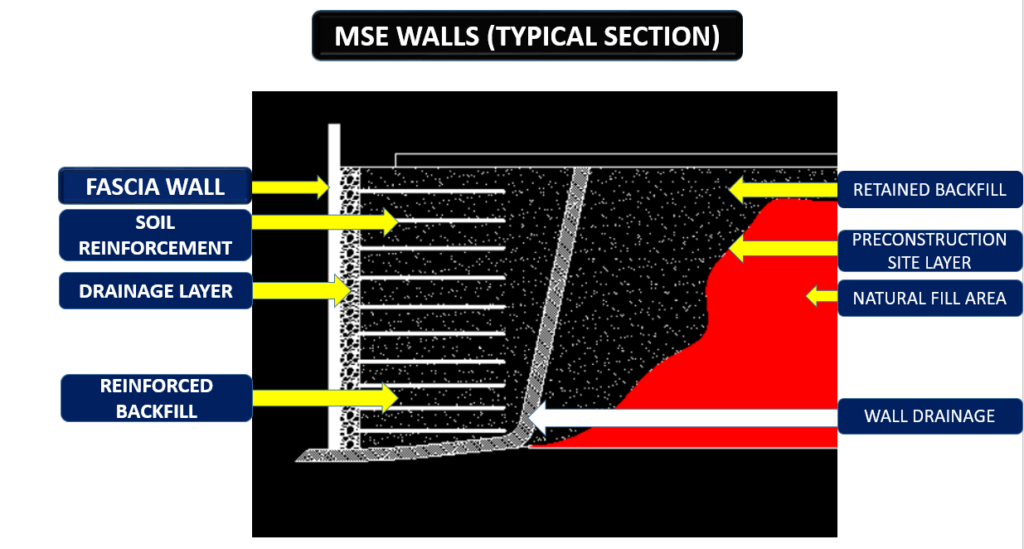

- Soil nails do not need any foundation or any structural whaler beams at the bottom like cantilever and anchored retaining walls.

- With the soil nailing method, we can reduce the duration of work, and fewer materials are consumed in this process.

- They are so flexible and easily customizable and nail location can be easily adjusted on encountering any obstructions.

- Small equipment is used for soil nailing works.

- They can accommodate differential settlements and deflection of soil nails are usually within tolerable limits.

- They are more cost-effective than any other retaining wall system. This is because shotcrete of minimal thickness is used, unlike the heavy structural walls in other retaining wall systems.

Key Takeaways

- Soil nailing is a slope stabilization method used in construction and excavation to reinforce soil structures.

- Soil nails are steel bars installed sub-horizontally in the ground to prevent landslides and erosion.

- The components of soil nails include tendons and grout, which provide reinforcement and corrosion protection.

- Installation begins from the top, with each layer secured with anchor plates, followed by shotcreting.

- Applications of soil nails include highway cut excavations, road widening, and deep excavations in urban areas.

- Soil nailing is cost-effective, fast, and requires minimal workspace compared to other retaining systems.

- This technique is not suitable for poorly graded, cohesion-less soils or areas with high groundwater tables.

Conclusion

Soil nailing is a versatile method for reinforcing slopes and retaining walls. It offers significant advantages in various geotechnical applications. It is particularly useful for highway projects, deep excavations, and slope stabilization. In these scenarios, soil nails provide crucial support to prevent landslides and erosion. The technique’s minimal workspace requirements, cost-effectiveness, and adaptability to different site conditions make it a popular choice in construction. Soil nails are most effective in soils that can stand unsupported for short periods. They should be used with caution in cohesion-less soils or areas with high groundwater levels. Overall, soil nailing offers a reliable solution for stabilizing slopes while maintaining project timelines and budgets.