Types of Spillway are essential structures provided in dams to safely pass excess floodwater and maintain reservoir levels. Every dam requires a suitable spillway system to prevent overtopping and structural damage. Different spillway types are used based on site conditions, discharge capacity, and dam design. In practice, spillways in dams guide surplus water away from the dam body while controlling flow energy. Each spillway in dam serves a specific purpose, whether for normal operation or emergency conditions. The spillway of dam may be gated or ungated, straight or curved, depending on hydraulic requirements. Engineers classify dam spillway types to ensure safety, efficiency, and long-term performance. This article explains the different types of spillway, their arrangement, major spillway components, and important spillway features that influence operation and durability.

Let’s start from the definition.

- What is a spillway ?

- Spillways of Dams – Role and Importance

- Components of a Spillway

- Dam spillway types – Classifications

- Conclusion

What is a spillway ?

A spillway is a hydraulic structure provided in a dam to safely release excess water from a reservoir to the downstream side. It prevents overtopping of the dam during floods and heavy inflows. The spillway in a dam controls water levels and protects the dam body from erosion and structural failure. By guiding surplus water through a designed channel, a dam spillway reduces pressure on the embankment or concrete structure. Different spillway types handle varying discharge conditions and flow rates. Proper spillway design ensures safe flood passage, energy dissipation, and long-term stability of dams and reservoirs.

Spillways of Dams – Role and Importance

Spillways of dams are vital hydraulic structures that ensure the safe and efficient operation of reservoirs. A spillway allows excess water stored in a dam to pass safely to the downstream side. This process happens in a controlled manner, especially during floods or heavy inflows. It acts as a safety valve when the reservoir reaches its maximum capacity. This prevents water from overtopping the dam. It also avoids structural damage or failure.

Importance of Spillways for Dams

The following are the importance of spillways of Dams

- Improve the long-term safety, stability, and durability of dams

- Prevent overtopping of the dam during floods and heavy inflows

- Safely discharge excess reservoir water to the downstream side

- Control floods and reduce downstream flood risks

- Regulate and maintain safe reservoir water levels

- Provide emergency water release during extreme conditions

- Reduce hydrostatic pressure on the dam body and foundations

- Protect embankments and structural components from erosion

- Dissipate flow energy and minimize downstream scouring

- Safeguard appurtenant structures such as gates and outlets

Let’s go on a trip to see the different types of spillway.

Components of a Spillway

Depending on the suitability of the site and other conditions, various types of spillways may be given. A spillway consists of three main components that work together to safely discharge excess water from a reservoir. Each component of spillway has a distinct function and hydraulic role.

Control Structure

The control structure is the upstream part of the spillway that regulates the release of water from the reservoir. It allows water to pass only when the reservoir level exceeds a predetermined safe level. This structure controls discharge capacity and prevents uncontrolled outflow during normal operating conditions.

Conveyance Channel

The conveyance channel carries water from the control structure to the downstream side of the dam. It follows open-channel flow principles and may be located on the dam body or along a natural slope near the dam. Its main role is to guide water safely without causing erosion.

Terminal Structure

The terminal structure dissipates the high kinetic energy of flowing water before it enters the downstream river. As a result, the flow rate at the downstream end of the spillway is extremely high. It causes damage to the dam, spillway, and other nearby structures. As a result, engineers dissipate the high flow energy before returning the water to the downstream river. They provide terminal structures at the downstream end of the discharge channel to reduce this excess energy.

The first two can be combined in some cases. Now we have seen the main parts of a spillway. Time to learn about the different categories.

Dam spillway types – Classifications

Dam spillway types are classified based on hydraulic design, site conditions, and discharge requirements. This classification ensures they can safely pass floodwater. It also protects dam structures from overtopping and failure.

Types of Spillways

- Drop Spillway

- Ogee Spillway

- Chute Spillway

- Side-Channel Spillway

- Shaft Spillway

- Siphon Spillway

- Conduit Spillway

- Culvert Spillway

Let’s discuss each of its features in detail.

Drop Spillway

A drop spillway is a type of weir structure where water flows through the weir opening and then drops onto a level apron or a stilling basin before finally entering the downstream channel. This arrangement helps manage excess water safely while controlling flow energy.

- The overflowing water descends freely and almost vertically on the downstream side of the hydraulic structure.

- This type of spillway is well suited for low dams and weirs.

- Engineers shape the spillway crest with a nose to prevent the water jet from directly striking the downstream foundation of the structure.

- On the downstream side, engineers provide a horizontal impervious apron to safeguard the structure against scouring caused by high-velocity flow.

- Engineers construct a basin is usually constructed on the downstream side to form a small artificial pool, commonly referred to as a water cushion.

- The primary purpose of this water cushion is to dissipate the energy of the falling water and reduce erosion.

Ogee type Spillway

An ogee type spillway is an overflow spillway with an S-shaped crest profile, hydraulically designed to efficiently pass floodwater while maintaining controlled pressure conditions over the crest.

- This is an overflow spillway with a controlled weir and a profile that is ogee-shaped (S-shaped).

- It’s designed to track the lower surface of a horizontal jet that emerges from a sharp-crested weir.

- At the design head, the pressure at the ogee crest remains atmospheric.

- At a lower head, the pressure on the ogee crest becomes positive.

- This results in the backwater effect which decreases the discharge.

- At a higher head, the pressure on the crest becomes negative, resulting in the backwater effect, which increases the discharge

Chute Spillway

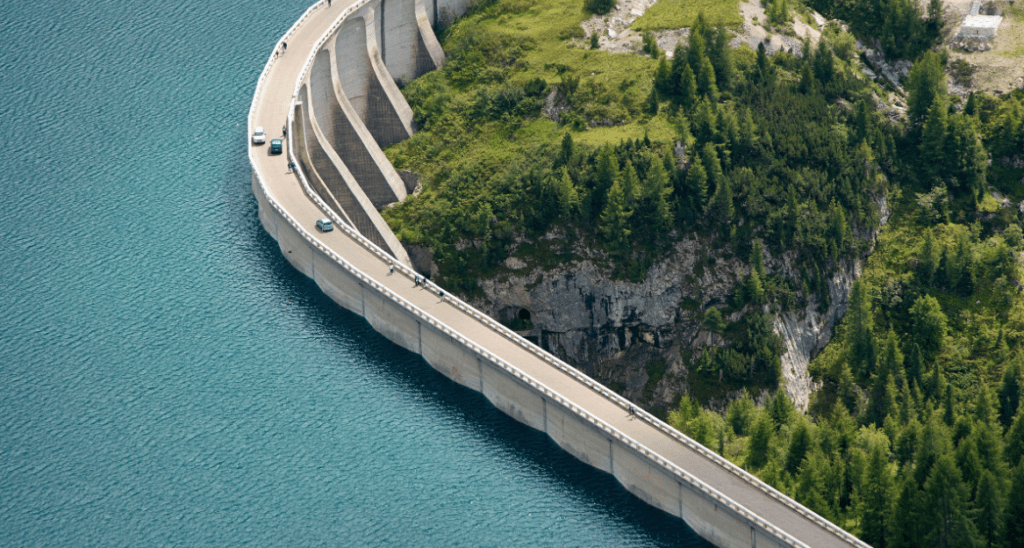

The chute spillway is an open channel-like structure with a fitting inlet and outlet built on the steep slope of the gully face.

- Also called Trough Spillway.

- The aim of the Chute Spillway is to protect the valley walls from damage that could put the dams in danger.

- It is made up of a reinforced concrete slab that is a steeply sloping open channel.

- The spillway is not always of the same width.

- It is normally narrowed for the economy and then widened at the end to reduce the discharging velocity.

Side-channel

A side channel spillway has a control weir that runs alongside and roughly parallel to the spillway discharge channel’s upper half.

- Unlike a chute spillway, the water spilling from the crest is turned 90 degrees and flows parallel to the crest of a side-channel spillway.

- When flanks of adequate width are not accessible, side-channel spillways are preferred over chute spillways, typically to prevent heavy cutting.

- The angle of turn of the water flow after passing through the weir crest can be held between 0 and 90 degrees. The spillway discharge falls into a shallow trough after flowing over the weir crest.

Shaft Spillway

- The water from the reservoir enters a vertical shaft in the shaft spillway, which transports the water into a horizontal tube.

- A Shaft Spillway is made up of a horizontal crest and a vertical shaft, with the top surface at the spillway’s crest level and the lower end attached to a vertical shaft.

- The vertical shaft’s other end is attached to a horizontal conduit or tunnel that runs through or around the dam and transports the water to the river below.

- When the conditions aren’t conducive to an overflow or a chute spillway, a shaft spillway is used.

Siphon Spillway

- The theory of siphonic action governs the operation of a siphon spillway.

- A siphon spillway consists of two siphon pipes.

- Engineers place one pipe upstream in contact with the reservoir, while the other pipe discharges water on the downstream side.

- They provide an airtight RCC cover, known as the hood, over an ogee-shaped concrete body wall to form the siphon duct.

- The top of the body wall forms the spillway crest, and engineers maintain it at the reservoir’s Full Reservoir Level (F.R.L.).

Conduit Spillway

- Made up of a closed conduit that transports floodwaters to a downstream channel.

- A vertical or inclined shaft, a horizontal tube, or a conduit built in an open cut and then covered are all examples of closed conduits.

- It is built in the abutment or underneath the dam.

- Dam sites in narrow canyons with steep abutments would benefit from such a spillway.

Labyrinth Spillway

- A labyrinth spillway is one in which the weir wall is built in a zigzag pattern to maximise the effective length of the weir crest in comparison to the channel width.

- This improvement in effective length increases the weir’s discharge capacity, allowing for more water flow at small heads to be easily transported downstream.

That’s it about spillway and their types. Hope you found it insightful. Next time you visit a dam site, make sure that you are able to identify the type of spillway present there. If you get confused don’t forget to check out our detailed articles on dams.

Key Takeaways

- Types of Spillway are crucial for safely managing excess water in dams and protecting against flooding and structural damage.

- Different spillway types include Drop, Ogee, Chute, Side-Channel, Shaft, Siphon, Conduit, and Labyrinth, each serving unique hydraulic functions.

- The components of a spillway consist of the Control Structure, Conveyance Channel, and Terminal Structure, working together to manage water flow.

- Proper spillway design enhances the safety and longevity of dams by controlling flow energy and maintaining reservoir levels.

- Understanding the various types of spillway aids in identifying their specific applications and importance in dam engineering.

Conclusion

Types of Spillway play a decisive role in ensuring dam safety and effective flood management. Understanding various spillway types helps engineers design reliable systems that safely pass excess water and protect structures. Properly designed spillways in dams regulate reservoir levels and prevent overtopping during extreme inflow conditions. Every spillway in dam consists of essential spillway components that work together to control flow and dissipate energy. The spillway of dam may differ in layout and function, but its objective remains safe water discharge. Clear spillway classification allows engineers to compare performance and select suitable dam spillway types for specific site conditions. Knowledge of the different types of spillway and their spillway features improves hydraulic efficiency, structural safety, and long-term durability. Overall, spillways are indispensable elements of modern dam engineering and flood control systems.