Types of beams popularly used In construction and engineering are classified based on their shape, the way they are supported, their structural behaviour etc. The beam is a horizontal or sloping structural member that supports a load and resists bending.In construction, beams are essential components that support loads and provide structural stability. This article explores the types of beams used in various applications, focusing on types of beam in building construction.We’ll cover what are the 4 types of beams, which are widely used in both residential and commercial projects. Additionally, we’ll discuss types of beams and support systems to understand how these beams interact with other structural elements. We’ll also examine different types of beams and their specific characteristics, along with popular beam types in modern construction. By the end, you’ll have a clear understanding of various type beams and their practical uses.

Beams are typically made from materials such as wood, steel, or concrete. They support floors, roofs, and walls. They also bridge gaps between supports. The type of beam used depends on factors such as the load to be supported, the span length, and the structural design of the building or structure. Beams can come in a variety of shapes, including rectangular, square, circular, and I-shaped. Proper selection and installation of beams are critical for ensuring the stability, safety, and durability of a structure.

This article is about the different types of beams popularly used in civil engineering and construction.

- Classification of beam types

- Types of beams based on support conditions

- Types of beams based on structural behaviour

- Types of beams based on materials used

- Key Takeaways

- Conclusion

Classification of beam types

Types of Beams can be classified based on several factors, including their shape, the way they are supported, and their structural behaviour. Here are some common classifications of beams.

Beams are vital components in construction, and understanding the different types of beams is essential for choosing the right structure. So, what are the 4 types of beams? Beams can be categorized in various ways. Beam types based on shape include rectangular, I-beams, and T-beams. Type beams are also defined by their support conditions, such as simply supported and cantilever beams. What are the 4 types of beams based on structural behavior? These include flexural, axial, shear, and torsional beams. Additionally, the types of beams in building construction are often selected by material, including concrete, steel, and wood beams. Understanding the types of beams and support ensures optimal performance in construction.

Related posts from vincivilworld

- Types of beams Based on the shape

Beams can be classified as rectangular, square, circular, I-shaped (also known as H-beam), T-shaped, and L-shaped.

- Types of beams Based on support conditions

Beams can be classified as simply supported, fixed, cantilever, continuous, and overhanging.

- Types of beams Based on structural behaviour

Beams can be classified as determinate or indeterminate. Determinate beams have a fixed number of supports and can be analysed using statics. Indeterminate beams have more supports than are needed for stability and require more advanced analysis techniques to determine their behaviour.

- Types of beams Based on the material

Beams can also be classified based on the material used, such as wood, steel, or concrete.

The choice of beam type depends on the load to be supported, the span length, and the structural design of the building or structure.

Types of beams based on the shape

Beams can be classified based on their shape, which refers to the cross-sectional profile of the beam. The shape of the beam affects its structural properties, such as its strength, stiffness, and weight. Here are some common shapes of beams.

Rectangular beam

A rectangular beam is a type of beam that has a rectangular cross-section. It is a simple and commonly used beam in construction due to its ease of fabrication and ability to support both bending and compression loads. Rectangular beams are typically made from materials such as wood, steel, or concrete.

Square beam

A square beam is a type of beam that has a square cross-section. It is commonly used in applications where a symmetric load is expected, and it provides uniform support in all directions. Square beams are typically made from materials such as wood, steel, or aluminium and are used in construction, manufacturing, and other engineering applications.

Circular beam

A circular beam is a type of beam that has a circular cross-section. It is commonly used in applications where torsion is a concern, such as in helicopter blades and wind turbines. Circular beams provide strength and stability in all directions and are typically made from materials such as steel, aluminium, or composite materials.

I-shaped (H-beam)

An I-shaped beam, also known as an H-beam, is a type of beam that has an I-shaped cross-section. It is commonly used in construction because of its high strength-to-weight ratio and ability to support large loads. I-shaped beams are typically made from steel. They are used in a variety of applications, such as bridges, buildings, and other infrastructure.

T-shaped beam

A T-shaped beam is a type of beam that has a T-shaped cross-section. It is commonly used as a lintel or in other load-bearing applications where a shallow beam is needed. T-shaped beams provide structural support in one direction. They are typically made from materials such as steel, wood, or reinforced concrete.

L-shaped beam

An L-shaped beam is a type of beam that has an L-shaped cross-section. It is commonly used as a bracket or in other applications where load-bearing support is needed. L-shaped beams provide structural support in two directions and are typically made from materials such as steel, wood, or reinforced concrete.

The choice of beam shape depends on the load to be supported, the span length, and the structural design of the building or structure.

Types of beams based on support conditions

Beams can also be classified based on their support conditions, which refers to how the beam is held in place. Here are some common support conditions for beams:

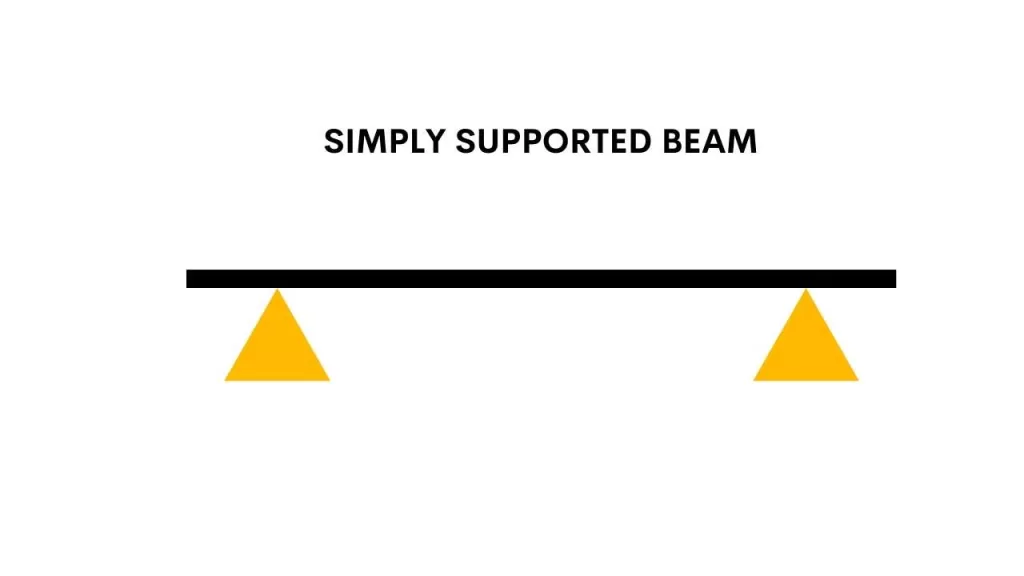

Simply supported beams

A simply supported beam is a type of beam that is supported at both ends and is free to rotate. It is one of the most common support conditions for beams and is used in a wide range of applications, such as bridges, buildings, and other infrastructure. Simply supported beams are typically used to support lighter loads and have a simple design.

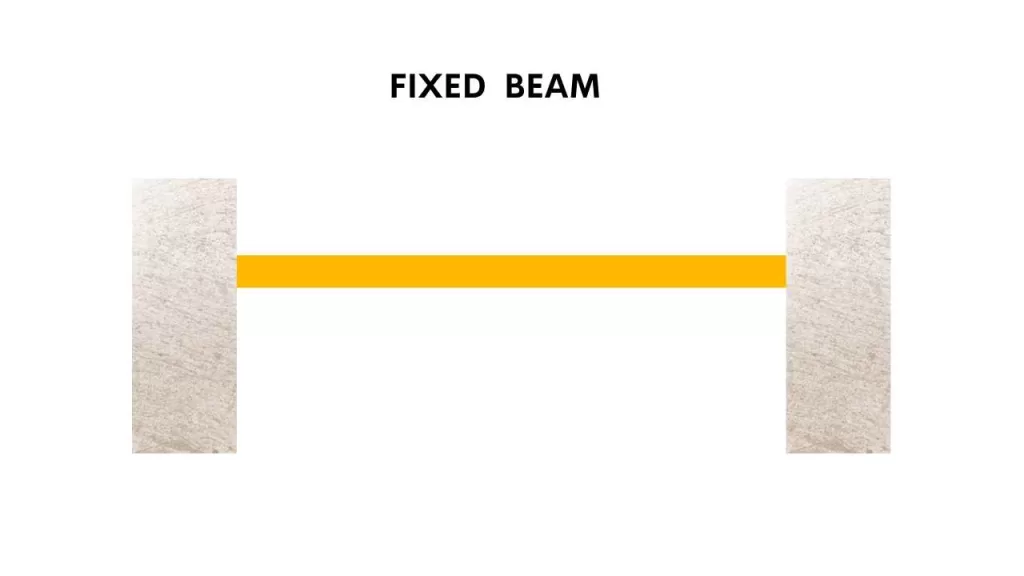

Fixed beams

A fixed beam is a type of beam that is rigidly fixed at both ends and cannot rotate. This support condition results in a beam that is capable of supporting heavier loads than a simply supported beam. Fixed beams are commonly used in construction. This includes the construction of tall buildings or other structures that require a high level of load-bearing capacity. However, the design of fixed beams is more complex than simply supported beams. This complexity arises due to the structural constraints imposed by the fixed supports.

Cantilever beams

A cantilever beam is a type of beam that is supported at one end and is free to rotate at the other end. It is commonly used in applications where an overhanging structure is required, such as in balconies or bridges. Cantilever beams are capable of supporting relatively heavy loads. They have a unique design that requires careful consideration of the forces acting on the beam.

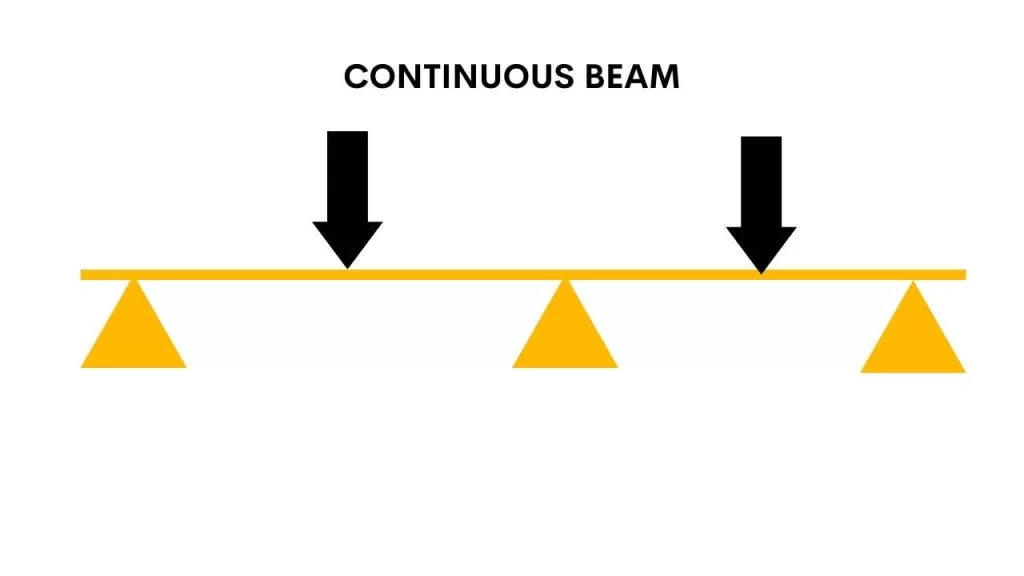

Continuous beams

A continuous beam is a type of beam supported by more than two supports. It has one or more internal supports. This support condition results in a beam that is capable of supporting heavier loads. It can support more than a simply supported beam or cantilever beam. Continuous beams are commonly used in construction. They are used in the construction of bridges or multi-story buildings. Careful consideration of the distribution of loads and internal support points is required.

Overhanging beam

An overhanging beam is a type of beam that extends beyond its supports and has one or more overhanging sections. This support condition results in a beam that is capable of supporting loads that are not symmetrical or evenly distributed. Overhanging beams are commonly used in construction. They are often used in the construction of balconies or awnings. These beams require careful consideration of the distribution of loads. This includes the structural design of the overhanging section.

The choice of support condition depends on the load to be supported, the span length, and the structural design of the building or structure. Different support conditions result in different load-bearing capabilities and structural behaviour for the beam, which must be taken into account during the design process.

Types of beams based on structural behaviour

Beams can be classified as determinate or indeterminate. Determinate beams have a fixed number of supports and can be analyzed using statics. Indeterminate beams have more supports than are needed for stability and require more advanced analysis techniques to determine their behaviour.

Types of beams based on materials used

Beams can also be classified based on the materials used in their construction. Here are some common classifications based on materials:

Timber beam

A timber beam is a type of beam that is made from wood. Timber beams are commonly used in residential and light commercial construction due to their relatively low cost, ease of construction, and natural aesthetic appeal. However, their strength and durability can be limited compared to other materials, which must be taken into account during design.

Steel beam

A steel beam is a structural element made of steel that is used to support loads over a span. It is typically I-shaped or H-shaped and comes in various sizes and lengths. Steel beams are commonly used in construction projects such as bridges, buildings, and infrastructure due to their strength and durability.

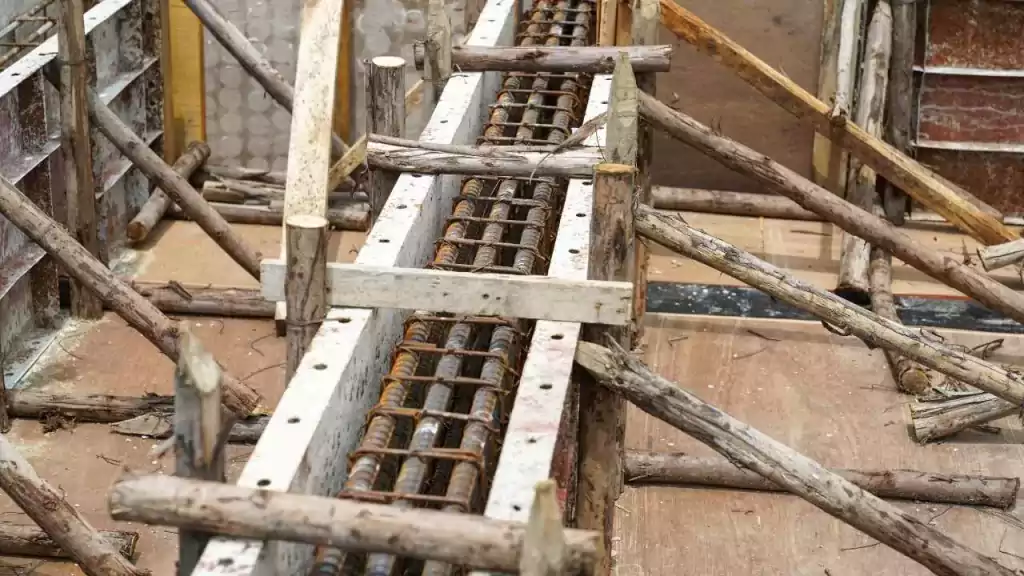

Concrete beam

A concrete beam is a structural element made of reinforced concrete that is used to support loads over a span. It is typically rectangular or T-shaped and comes in various sizes and lengths. Concrete beams are commonly used in construction projects such as buildings, bridges, and infrastructure due to their strength and durability.

Composite beam

A composite beam is a structural element made of a combination of different materials, typically steel and concrete, that work together to support loads over a span. The steel and concrete are bonded together to create a strong, durable beam that can be used in construction projects such as buildings, bridges, and infrastructure.

The choice of material depends on the load to be supported, span length, and other design requirements. Each type of beam has unique structural properties that must be taken into account during the design process to ensure that the beam can support the intended loads.

Key Takeaways

- Beam Types in Construction: Beams are classified based on their shape, support conditions, structural behavior, and material.

- Shape-Based Beam Types: Rectangular, square, circular, I-shaped, T-shaped, and L-shaped beams are used depending on load requirements and structural design.

- Support Conditions: Beams can be simply supported, fixed, cantilever, continuous, or overhanging, each offering different load-bearing capabilities.

- Structural Behavior: Beams are categorized as determinate or indeterminate, influencing how they are analyzed in design.

- Material-Based Beam Types: Common materials include timber, steel, concrete, and composite materials, each with unique properties for different applications.

- Beam Selection: Factors like load, span length, and structural stability influence the choice of beam types in building construction.

Conclusion

Beams are fundamental components in construction, supporting loads and providing structural stability. They can be categorized based on shape, support conditions, material, and behavior. Each type is designed to meet specific structural demands. Rectangular and I-shaped beams are commonly used in buildings and bridges. Cantilever beams are perfect for overhanging structures. The correct selection of beam types is essential to ensure safety, durability, and performance in any construction project. Understanding the various beam types helps in designing more efficient and stable structures.