Development length is an essential concept in civil engineering that refers to the length of reinforcement required to transfer the force from the steel reinforcement to the surrounding concrete. It is crucial in ensuring that the reinforcement is effectively bonded to the concrete to resist the applied forces. “The development length depends on several factors, including the diameter of the bar and the strength of the concrete. “Another factor that affects the development length is the bond strength between the steel reinforcement and the surrounding concrete.”

Properly understanding development length is essential for designing reinforced concrete structures to ensure their safety and stability. Engineers calculate the development length to ensure that the reinforcement will provide the intended strength and reinforcement to the structure. “Insufficient development length can cause the reinforcement to fail to transfer forces to the concrete effectively. This can ultimately lead to structural failure.”

What is the development length?

To develop the full tensile strength of the reinforcement, one must embed the reinforcement in concrete for a minimum length known as the development length. This is necessary to ensure that the reinforcement can resist the applied loads. This should happen without pulling out of the concrete or causing concrete failure.

Either pull-out or splitting failure modes typically control the length. In pull-out failure, the force applied to the reinforcement exceeds the pull-out strength of the concrete. This generally causes the reinforcement to pull out of the concrete. In splitting failure, the force applied to the reinforcement causes the concrete to crack and split. This can lead to the failure of the reinforcement.

Related posts from vincivilworld

Significance and functions

This is a critical concept in reinforced concrete structures that ensures the effective transfer of forces and prevents premature failure. It is important for the safety and stability of structures and is a crucial factor in their design and construction. The main function is as follows.

Transfer of applied forces

Ensuring effective bonding of the steel reinforcement to the surrounding concrete is the purpose of the Development length in reinforced concrete structures. This allows it to transfer the applied forces to the concrete.

Prevents structural failure:

Basically, the proper bonding of the reinforcement to the concrete prevents premature failure of the structure. This could otherwise result in catastrophic consequences.

Important for design

Properly understanding Develop length is critical for designing reinforced concrete structures. Engineers must calculate the length to ensure that the reinforcement provides the intended strength and reinforcement to the structure.

Basically, an insufficient development length can lead to the reinforcement not being able to transfer the forces to the concrete effectively. However, this results in premature failure and instability.

Structural safety and stability

Generally, this is crucial for the safety and stability of reinforced concrete structures. The failure to effectively bond the reinforcement to the concrete would result in the inability to transfer the applied forces. However, this can lead to structural failure.

Factors determining Development strength

Several factors influence the required development length to fully develop the tensile strength of reinforcement in concrete, including

- Reinforcement properties: The strength and diameter of the reinforcement significantly impact the required development length. Generally, high-strength reinforcement with a larger diameter will require a longer D length to develop its full strength.

- Concrete properties: The strength, stiffness, and thickness of the concrete member where we place the reinforcement are crucial factors. However, a higher concrete strength requires a longer d length, while a thicker concrete section may require a shorter length.

- Bond strength: The bond strength between the reinforcement and concrete is critical in determining the development length. However, the bond strength depends on various factors. This includes the surface condition of the reinforcement, the degree of deformation, and the quality of the concrete surface.

- Environmental conditions: Environmental factors such as humidity, temperature, and exposure to corrosive agents can affect the bond strength between the reinforcement and concrete. In such cases, we may require a more extended development length.

- Load conditions: The type, magnitude, and direction of the load applied to the reinforcement significantly influence the development length required. Generally, Higher loads require a longer D length to prevent the reinforcement from pulling out of the concrete.

- Design codes and standards: Design codes and standards typically provide guidelines for determining the minimum development length required for different types of reinforcement and loading conditions. However, these guidelines may vary depending on the specific code or standard used.

Development length as per IS 456

Basically, Clause 26.2.1 of the Indian code for the design of reinforced concrete structures (IS 456:2000) provides the formula to calculate the development length of reinforcement bars in tension. Basically, we require the length of the reinforcement bar to transfer the stresses between the reinforcement and the surrounding concrete.

The formula for calculating the D length (Ld) of a reinforcement bar with a diameter of D, embedded in concrete with a grade of M, and subject to tension, is as follows:

Ld = (0.87 fy A / 4τ_bd) + (0.2 √fc) …Equation 1

where:

- fy is the characteristic strength of the reinforcement in N/mm²

- A is the area of the reinforcement in mm²

- τ_bd is the bond stress between the reinforcement and the surrounding concrete in N/mm²

- fc is the characteristic compressive strength of concrete in N/mm²

The first term in Equation 1 represents the basic development length, which is the minimum length required for the reinforcement to fully develop its strength. The second term represents the additional development length due to the curvature of the bar.

It is worth noting that the code also provides alternative methods for calculation, such as the empirical equations given in Table 5 of the code. However, Equation 1 is the most widely used method for calculating the development length in India.

It is important to note that these calculations are based on certain assumptions and simplifications, and the actual development length required may vary based on the specific design requirements and site conditions.

Development length as per IS 456 for columns, footings and beams

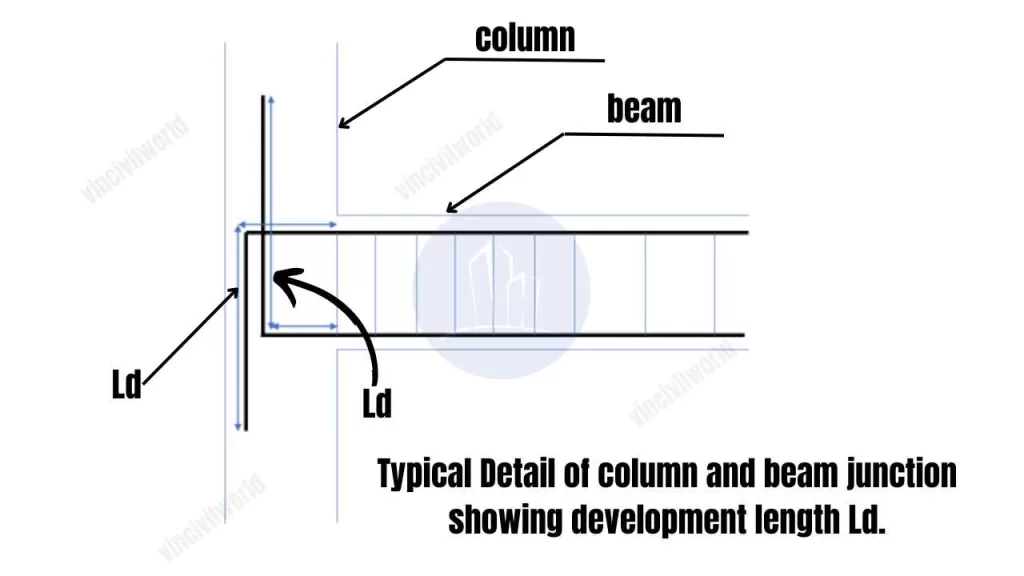

The dev. length of rebars is the minimum length required for the effective transfer of forces from the steel reinforcement to the surrounding concrete. However this ensures that the reinforcement is properly bonded to the concrete, preventing premature failure of the structure.

Typical section beam-column junction

Development length as per codes

The development length of a reinforcing bar, or rebar, is the minimum length of the bar that must be embedded or overlapped with concrete to ensure proper transfer of stresses between the concrete and steel. This is a critical design parameter, and it is determined based on various factors such as the strength of the rebar, the strength of the concrete, and the design requirements of the structure.

Here are the formulas as per some commonly used codes:

ACI 318-19 (American Concrete Institute)

Ld = [(φ x Fy x As) / (4 x Fc’^(0.5))] x (1.3 for deformed bars, 1.7 for plain bars)

where: Ld = development length in inches

φ = strength reduction factor (0.7 for deformed bars, 0.8 for plain bars)

Fy = yield strength of rebar in ksi

As = area of rebar in square inches

Fc’ = specified compressive strength of concrete in psi

BS 8110-1:1997 (British Standard)

Ld = [(1.2 x σst x As) / (0.87 x Fy x (1 + (200/d))^(0.5))] x (1.4 for deformed bars, 1.7 for plain bars)

where: Ld = development length in mm

σst = stress in rebar at yield in N/mm2

As = area of rebar in mm2 Fy = characteristic yield strength of rebar in N/mm2 d = diameter of rebar in mm

IS 456:2000 (Indian Standard)Ld = [(0.87 x fy x As) / (4 x τbd x fck^(0.5))] x (1.2 for deformed bars, 1.6 for plain bars)

where: Ld = development length in mm

fy = characteristic strength of rebar in N/mm2

As = area of rebar in mm2 τbd = design bond stress in N/mm2

fck = characteristic compressive strength of concrete in N/mm2

It is important to note that the development length calculation may vary based on the specific requirements of the structure, and it is recommended to consult the appropriate code for accurate and up-to-date information.