Bitumen types for road layers are a vital topic to comprehend when it comes to road construction. Bitumen is preferred for flexible pavements in road construction because it has many advantages over other pavement construction materials. This article will demonstrate the importance of bitumen in road construction and the types of bitumen for road construction. Furthermore, bitumen emulsion types for road layers, different bituminous materials, cutback bitumen, bitumen grade, and bitumen attributes will be highlighted in this article.

Bitumen types for Road layers /Flexible pavements

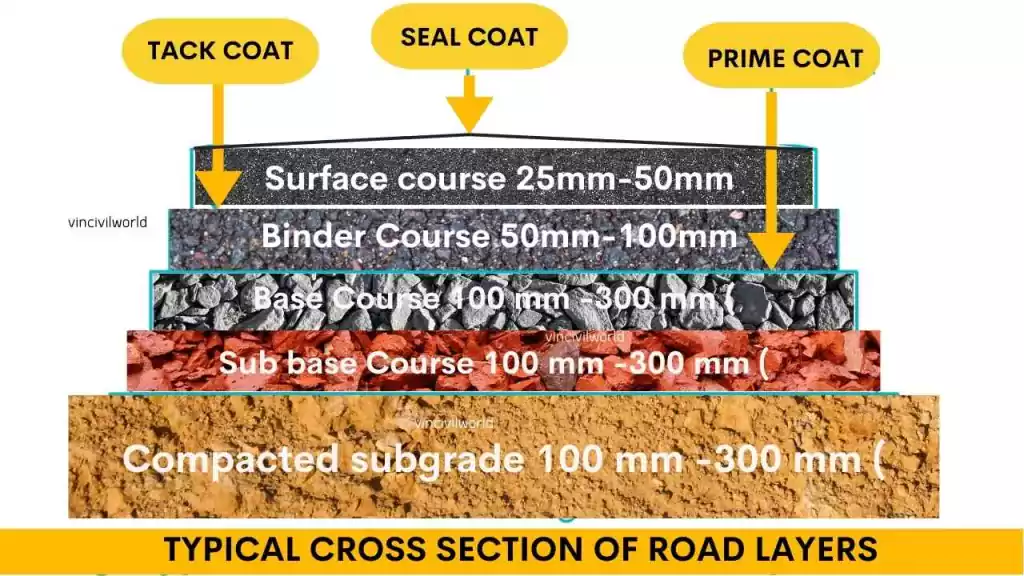

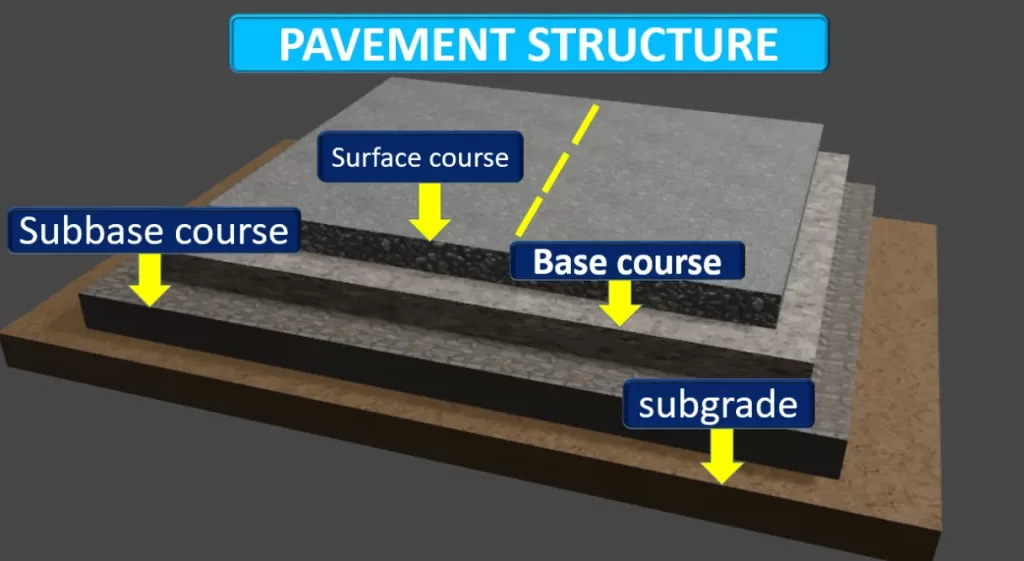

The flexible pavement structure consists of the following layers:

- Tack Coat

- Binder Course

- Prime Coat

- Base Course

- Subbase Course

- Subgrade Course

Keep in mind that the primary component of the road is not protective asphalt. Protective asphalt is deployed to safeguard the road’s surface. Every layer mentioned above uses a different type of bitumen. We will illustrate what types of bitumen are used in each of these layers.

Tack Coat – Bitumen types for road layers

The application of coatings is a critical phase in the construction of asphalt roadways. Generally, a tack coat is a thin layer of asphalt emulsion or liquid bitumen used in between layers of hot mix asphalt to prevent slippage. Mostly, MC30 cutback bitumen, CRS-1, and CRS-2 emulsion bitumen are utilised in a tack coat layer of bitumen. The lower layer is sealed by the presence of a tack coat, which also increases the strength of both asphalt layers.

MC-30 is a medium-curing cutback bitumen that is ideal for cold climates. Basically, asphalt emulsions are the most often used tack coat materials. However, the most widely used slow-setting emulsions are SS-1, SS-1h, CSS-1, and CSS-1h (1). The usage of rapid-setting asphalt emulsions like RS-1, RS-2, CRS-1, and CRS-2 for tack coats is also on the rise.

Related posts from vincivilworld

Binder Course – Bitumen types for road layers

The base course and the surface course are separated by the binder course. Generally, a binder course is used to keep the road surface from moving. Because the binder course is made out of coarse aggregates, less bitumen is utilised in the manufacture of this asphalt. In the hot asphalt of the binder course, various grades of pure bitumen can be utilised. The various grades of pure bitumen used in binder courses are listed in the table below.

| Penetration Grade | Viscosity Grade |

| 30/40 | VG 10 |

| 40/50 | VG 20 |

| 60/70 | VG 30 |

| 80/100 | VG 40 |

| 120/150 |

Prime Coat – Bitumen types for road layers

A prime coat is a coating that is applied directly to the base layer. The primary objective of utilising the prime coat is to improve the bond between the base layer and the asphalt mix layer. It also fills in the voids. A priming coat might aid in sealing the base layer. The bitumen in prime coatings is either CSS or CMS.

Prime coats aid in reducing dust while protecting the granular base’s integrity throughout construction. In the event of a foundation that will be covered with a thin hot mix layer or a chip seal for a low-volume roadway, priming enables a good bond between the seal and the underlying surface, which might otherwise delaminate.

A primary coat is primarily responsible for safeguarding the substrate of a construction project before applying additional layers. They can also function as a binder with secondary and tertiary compounds in the preparation of asphalt, improving the adherence of the layers. Following the prime coat, a tack coat is applied to provide an adhesive bond between the tack coat and the subsequent layer of coating. For asphalt prime coat systems, the tack coat is one of the most vital parts of the process, as it connects the subsequent layers and forms the base of those layers’ strength.

Base Course

The base course is placed directly on top of the subbase course. This layer has a higher permeability than the sub-base layer because it is composed primarily of coarse aggregates. Basically, the base course, which is the first layer in direct contact with traffic, moves the weights from the upper layers to the sub-base course. Different base courses used in pavement include sand or stone base, macadam base, and bitumen base.

Sub Base Course

The first layer of flexible pavement constructed on the ground is the sub-base course. This layer is typically composed of river sand, an alluvial cone, and broken rock. Bitumen and cement can be used to stabilise the sub-base soil.

Sub Grade

It is the surface upon which further pavement layers such as the sub-base course, base course, and asphalt layers are placed. The subgrade absorbs any load tension or weight that is transferred from the top levels. A good subgrade should be able to support weights for a considerable amount of time without deforming.

Protective Asphalt

Generally, Protective asphalts are used to seal the road surface and improve the asphalt temporarily. However, It should be noted that asphalt sealing can cause the asphalt to become more slippery. Pure bitumen with low humidity and soluble bitumen are both utilised in protective asphalt. Because of its quickness and ease of installation, protective asphalt is more cost-effective than hot asphalt. There are various varieties of protective asphalts, some of which are listed below:

- Seal coat

- Slurry seal

- Chip seal

- Micro-surfacing

- Fog seal

Seal coat

A seal coat is used to provide a long-lasting surface texture and to keep the surface waterproof. However, this kind of protective asphalt can be made using a variety of emulsion bitumen types, including CSS-1, SS-1h, SS-l, and CSS-1h.

Slurry Seal

Generally, a slurry seal is used to lessen the harm done by bitumen oxidation. In the slurry seal, emulsion bitumens SS-1, SS-h1, CSS-1h, and CQS-1h are used. A slurry seal is appropriate for pavements with little to moderate damage, such as narrow cracks. However, it is not appropriate for severe damage such as holes.

Chip Seal

A chip seal is a thin protective surface that is applied to a pavement or subgrade. Water cannot easily seep through the base layer due to the chip seal. This layer also prevents freezing in areas where the temperature is below zero. Adding this layer improves the road’s reflectiveness for nighttime driving. A rapid-setting emulsion containing a CRS-2, RS-2, HFRS-2, and PMB is the best type of bitumen for chip sealing.

Micro Surfacing

Micro-surfacing aids in the sealing of cracks and the protection of existing bituminous layers against surface voids and minor ruts. Among the benefits of adopting this layer are environmental compatibility, cost-effectiveness, and fast construction time. PMB bitumens such as PMCQS-1h, PMQS-1h, and CQS-1P are suited for it.

Fog Seal

A fog seal is intended to neutralise the oxidation process that occurs over time. This layer protects the pavement surface by leaving a hard layer. This layer employs emulsion bitumen such as SS-1, SS-1h, CSS-1, or CSS-1h.