The ultrasonic pulse velocity test, or UPV test, is an example of a non-destructive concrete test. Generally, hardened concrete is subjected to non-destructive testing (NDT) and destructive tests (DT). Concrete is the world’s oldest and most significant construction material. Therefore, concrete testing is crucial for assessing the stability, strength, durability, and condition of structures.

Non-destructive testing of concrete is a way of analysing concrete structures without causing damage. This aids in ensuring the structural quality and condition. The strength of the concrete is also influenced by various characteristics, including hardness, density, curing circumstances, ingredient quality, workability and water-to-cement ratio, etc.

This article discusses the UPV test, which is one of the most well-liked and reliable non-destructive tests carried out on concrete structures.

- Ultra sonic Pulse Velocity test (UPV Test)

- Relevant IS code for Ultrasonic Pulse Velocity Test (UPV Test)

- Ultrasonic Pulse Velocity tester

- Principles of Ultrasonic Pulse Velocity test

- Objective of UPV tests

- Factors affecting Ultrasonic pulse velocity test

- Methodology of Ultrasonic Pulse velocity tests

- Result interpretation of UPV testing

- Conclusion

Also read : Bitumen tests – 9 tests for flexible pavements

Ultra sonic Pulse Velocity test (UPV Test)

The most efficient and fast method of testing concrete is through ultrasonic pulse velocity tests, or UPV tests. The quality of concrete is assessed using the results of UPV tests, which evaluate the period of travel of ultrasonic pulse waves. A 50–55 kHz range must be maintained for the ultrasonic pulse wave’s frequency. The pulses are generated by the UPV tester’s pulse generator and are allowed to travel through the concrete. By monitoring the traversing distance and the duration, the pulse velocity can be determined. Higher velocity indicates that the density and elastic modulus of the concrete are higher.

Cracks and defects in the structure are detected using UPV tests. Significant variations in pulse velocity values are indicative of broken and degraded concrete. The concrete’s density and wave velocity are related. Therefore, this test has a tremendous potential for evaluating the quality of concrete.

Relevant IS code for Ultrasonic Pulse Velocity Test (UPV Test)

IS-13311 (Part 1):1992 (Reaffirmed- May 2013) “Non-Destructive Testing of Concrete- Methods of Test (Ultrasonic Pulse Velocity)”

Related posts from vincivilworld

Ultrasonic Pulse Velocity tester

The UPV tester is the name of the type of equipment used to measure ultrasonic pulse velocity. The following accessories are included in ultrasonic pulse velocity tester.

- Electrical Pulse generator

- Pair of Transducers (probes)

- Amplifier

- Electronic timing device

Principles of Ultrasonic Pulse Velocity test

The electrical pulse generator generates pulses that are sent through the UPV tester’s transducer. Through the concrete surfaces, the pulse generates many reflections. Using the formula shown below, the pulse velocity is calculated.

Pulse velocity, V = L/T

where L is the traverse distance, T is the time for the receiver to receive the pulse

The geometry of the material is unrelated to the UPV test. Better concrete strength is associated with higher velocity and vice versa. One of the dynamic tests for concrete is the ultrasonic pulse velocity test.

Objective of UPV tests

The main objectives of the ultrasonic pulse velocity test or UPV tests are

- To learn the homogeneity of the concrete.

- Determines the presence of cracks, voids and imperfections.

- To calculate the elastic modulus of concrete.

- Finds the quality of concrete relative to the standard requirements.

- To determine the age of concrete.

Factors affecting Ultrasonic pulse velocity test

The UPV test detects cracks and assists in structure development. However, a number of factors influence how pulse velocity is measured. As a result, compressive strength cannot generally be approximated from the pulse velocity. The following are the elements that impact the UPV test.

- Presence of reinforcement

- Water content

- Mix proportion

- Temperature of concrete

- Concrete age

- Stress level of concrete

Methodology of Ultrasonic Pulse velocity tests

Piezoelectric and magneto strictive types of transducers are suitable for use with the UPV test. Additionally, its frequency range should be between 20 and 150 kHz. The electronic timing device monitors time with an accuracy of 0.1 microseconds.

The transducer transmits the waves that travel through the concrete surface. The receiver transducer detects the electric signals that are generated once the pulse waves are transformed to them. The traversal length will be displayed as ( L). The electronic timing device calculates how long it takes for signals to arrive. Time is shown as (T).

The Electronic timing device measures the receiving time of the signals. The time is denoted as (T).

Pulse velocity (v) = L/T

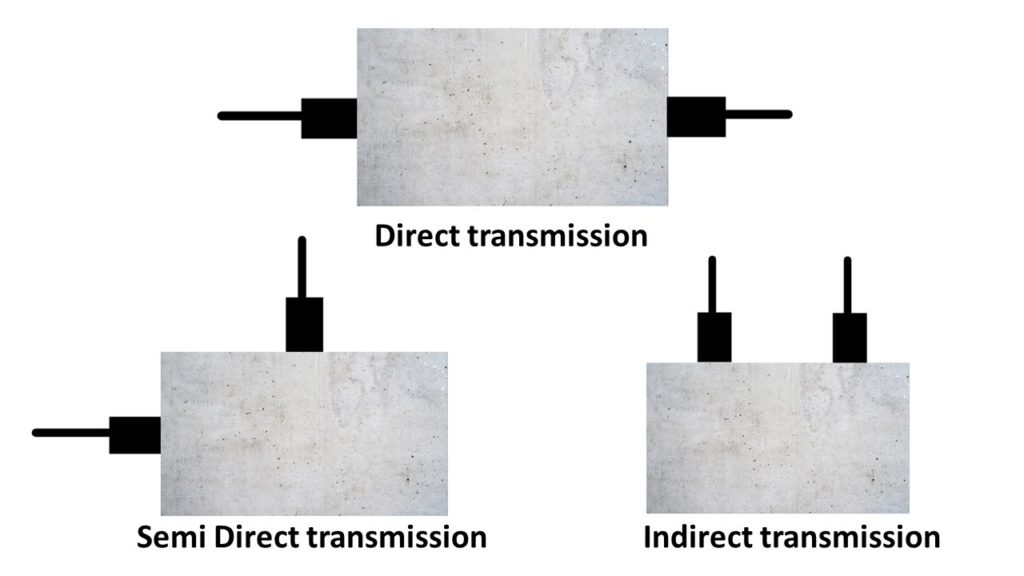

There are three common methods for doing UPV tests. They are direct method and indirect method.

- Direct Method of UPV Testing

- Indirect Method of UPV Testing

Direct method

The maximum energy is transmitted at right angles to the face of the transmitter. As a result, to achieve the greatest results, the receiving transducer must be placed on the side of the transmitting transducer. This is referred to as the direct approach or cross probing.

Indirect method

In some circumstances, the opposite side of the structure may be inaccessible. The receiving and transmitting transducers are installed on the same face of the concrete members in this scenario. This is known as the indirect method or surface probing. This approach is less effective than the direct approach. The test findings are mostly influenced by the surface concrete, which has different properties from the structural components’ core concrete.

Result interpretation of UPV testing

The density and elastic modulus of concrete are correlated with the ultrasonic pulse velocity. This in turn depends on the components, mixing processes, placement techniques, concrete compaction and curing, casting temperature, etc.

The main causes of internal cracks and pockets in concrete are lack of compaction and concrete segregation. Lower pulse velocity values are a result of these concrete defects. However, the laboratory tests might have confirmed a well-designed concrete.

The range of pulse velocity in the direct method is as shown below.

- Above 4.5 Excellent

- 3.5 to 4.5 Good

- 3.0 to 3.5 Medium

- Below 3.0 Doubtful

Conclusion

The final assessment of compressive strength from UPV is not the sole criterion used to determine concrete strength. The strength is confirmed by comparing it to a compressive strength estimate derived from the same ingredient mix and conditions. The results of the UPV test and site tests conducted using similar ingredients may be correlated. When compared to actual UPV intensities, the numbers may change by about 20%.