Progressive house design is a paradigm shift in residential architecture. This form of flexible architecture accepts change as an inherent part of life, creating a home that can physically adapt and expand to meet the evolving needs of its occupants. Unlike a static house, this embodies the very essence of adaptable housing, making the home a living entity. It is a testament to the fact that people’s lives are in a constant state of flux, thus creating a truly future-proof house. The strategy involves staged home building, where the home’s growth is carefully planned in successive phases. This modern approach often utilizes modular home construction, which makes all expansions efficient, predictable, and highly cost-effective.

This article will detail how to design a progressive house design, exploring its benefits, strategies, and the architect’s role.

- The Problem with “Static” Houses

- Strategies for Designing a Progressive House

- The Role of the Architect and Design Work

- The Advantages of a Progressive House Design

- Key take aways

- Conclusion

The Problem with “Static” Houses

Most houses are built with the assumption that the owners’ needs will remain constant, leading to several issues:

- Material Rigidity: They are often constructed using heavy, rigid materials. This makes interior or exterior modifications a complex and costly endeavor.

- The “Final” House Mindset: The prevailing belief is that a house is a one-time, final investment. This leads to designs that are over-scaled for current needs. They often assume a future that may never fully materialize.

- Standardized Shortcomings: Manufacturers mass-produce many prefabricated or standardized homes with a “one-size-fits-all” mentality, so they lack equipment for future adaptation.

This static approach is a stark contrast to the fluid nature of a progressive house design. It is inherently a future-proof house and is the equivalent of a lightweight, manoeuvrable sailboat. It is economical and can easily adjust its course as conditions change.

Strategies for Designing a Progressive House

Designing a progressive house is not about guessing the future. It is about intelligent planning and design. It’s about creating a blueprint that allows for growth in a logical, phased manner, a key principle of staged home building. Children’s products are often designed to adapt to their rapid growth. Similarly, a progressive home’s initial construction perfectly suits immediate needs. It also prepares for future expansion. The entire process is a clear roadmap for creating true adaptable housing/progressive house design.

Here’s a practical guide based on a common scenario: a couple starting their family.

- Identify Current Needs: List the essential rooms and spaces required for your life right now. For a couple, this might include a master bedroom, a home office, a single bathroom, a kitchen, and a living area.

- Anticipate Future Needs: Think about potential life changes. List the spaces that will be required to accommodate them. This could include two additional children’s rooms, a guest bathroom, a dedicated laundry room, or a garage.

- Define and Prioritize Stages: Break down the construction into clear, manageable stages. This is the core of adaptable housing.

- Stage 1: Construct the essential core.

- Stage 2: Build the additions for the growing family.

- Stage 3: Add the remaining desired spaces.

This phased approach provides a clear financial and logistical roadmap for your home’s development.

The Role of the Architect and Design Work

The architect is a crucial partner in this process. Their role is to educate clients and provide design alternatives. This embodies flexible architecture. This progressive mindset is not yet widespread. As a result, clients don’t ask for it, and architects don’t offer it. However, some innovative firms like La Panadería are championing this approach. They view the home as a continuous, collaborative process and a prime example of modular home construction.

When working on the progressive house design, consider these technical strategies:

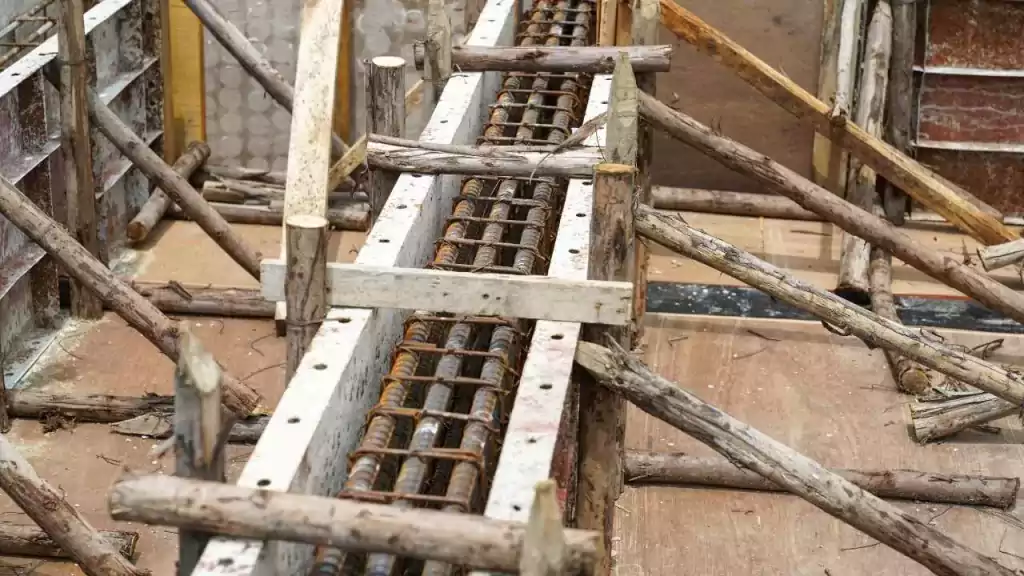

- Modular Home Construction: Choose a system that allows for easy and seamless expansion.

- Lightweight Interior Walls: Use materials like drywall that are easy to remove or relocate.

- Strategic Plumbing and Electrical: Install plumbing in foundational walls to accommodate future bathrooms.

- To future-proof the structure, engineers should design the foundation and roof from the start. This prevents the need for major structural overhauls later.

The Advantages of a Progressive House Design

Embracing a progressive house design offers numerous benefits:

- Financial Flexibility: You can spread the total budget for your home across multiple stages. You can invest incrementally as your financial situation allows.

- Cost and Time Efficiency: A smaller initial build is less expensive. It also takes less time to complete. This is a key advantage of staged home building.

- Lower Initial Investment: You only pay for the space you need right now. This makes homeownership accessible with a much smaller upfront budget.

- Increased Manageability: A smaller project is easier to oversee and manage. This reduces stress and potential complications.

- Acquired Experience: You gain invaluable hands-on experience during the first stage. This makes subsequent expansions a smoother, more confident process.

In conclusion, a progressive house design is a smart, strategic choice. It represents a shift from static, permanent structures to adaptable housing. This truly reflects the dynamic nature of human life. It’s a powerful antidote to the cost and complexity of a “definitive” house. With smart planning and a modular home construction approach, you can build a home that is always ready for what comes next.

Key take aways

Progressive house design is a strategic architectural approach that transforms static homes into dynamic, evolving living spaces. It’s a form of flexible architecture that fully embraces life’s constant changes.

This concept is centered on staged home building. By carefully building in phases, homeowners can spread out costs, which makes homeownership more financially accessible and entirely manageable for any budget.

A progressive home is a truly future-proof house. You can create adaptable housing where you quickly reconfigure rooms to suit different needs, like turning an office into a child’s nursery.

The process often relies on modular home construction. This efficient method uses prefabricated components to make future expansions and modifications seamless, quick, and remarkably cost-effective.

Conclusion

In conclusion, progressive house design offers a forward-thinking alternative to traditional static homes. This is a form of flexible architecture that embraces a strategic and planned approach to growth. Staged home building allows for a more financially manageable journey into homeownership. It’s a truly future-proof house that provides the ultimate form of adaptable housing by evolving with its occupants. By relying on modern techniques like modular home construction, you can make the expansion process efficient, predictable, and remarkably cost-effective.