Slipform shuttering is a continuous construction method. In this method, concrete is poured into a continuously moving formwork. This allows for the seamless creation of vertical structures. This technique, known as slipforming, enables the efficient construction of tall edifices such as silos, chimneys, and core walls in high-rise buildings. By employing slipform formwork, builders can achieve monolithic structures without horizontal joints. This method enhances the overall strength and durability of the construction.

The slipform formwork construction process involves the gradual and steady upward movement of the formwork system. This movement is synchronized with the setting rate of the concrete. This ensures that as the formwork ascends, the concrete below has gained sufficient strength to support itself. The continuous nature of slipform shuttering not only accelerates the construction timeline but also reduces labor costs and minimizes the need for scaffolding, making it a preferred choice for large-scale vertical constructions.

The blog will explore the definition and principles of Slipform shuttering, its key components, and the process of slipforming. We will highlight its advantages, common applications, and critical considerations for effective use. Additionally, we will discuss how Slipform formwork construction enhances efficiency and provide insights into best practices for successful implementation.

- What is Slipform Shuttering?

- Slipform formwork construction

- Historical Development of Slipform formwork construction

- Key components of slipform system

- Types of slipform shuttering

- Advantages of Slipform Formwork Construction

- Challenges and disadvantages of Slipform Shuttering

- Applications of Slipform shuttering

- Advancements in slipform construction

- Conclusion

What is Slipform Shuttering?

Slipform shuttering is an advanced construction technique. It enables the continuous pouring of concrete for vertical structures like silos, chimneys, and high-rise cores. The method employs slipform formwork construction, where the formwork system moves steadily upward, synchronized with the concrete’s setting time. This ensures seamless, monolithic structures without horizontal joints.

Significance and Development

The development of slipforming revolutionized construction by enhancing efficiency and reducing project timelines. This method eliminates the need for scaffolding, minimizes labor costs, and ensures structural integrity. Slipform shuttering has become integral in modern construction. It is especially useful for projects requiring tall, uniform structures. This is due to its ability to streamline processes while maintaining high-quality results.

Slipform formwork construction

The slipform formwork construction method basically rely on the following factors

Continuous Pouring and Synchronized Upward Movement

In slipform shuttering, concrete is poured continuously into a moving formwork system, which climbs steadily as the concrete sets. This synchronized upward movement ensures a seamless structure, eliminating horizontal joints and enhancing strength.

Importance of Concrete Setting Time

The climbing speed of the formwork is carefully calibrated to match the concrete’s setting time. If the formwork ascends too quickly, the concrete may deform due to insufficient strength. Conversely, if it moves too slowly, delays and uneven surfaces can occur. Maintaining this balance is crucial for structural integrity and efficiency. Proper synchronization is essential. It ensures that the concrete beneath the formwork gains enough strength to support its weight. It also needs to withstand construction loads during the process.

Historical Development of Slipform formwork construction

Slipforming has a rich history dating back to the early 20th century. The first slipform systems were primarily used for concrete roads and canals. Over the years, significant technological advancements have led to the development of sophisticated slipform systems that can handle complex structures and challenging environments. Some key milestones in the development of slipforming include:

- Early 20th Century: The first rudimentary slipform systems were used for road and canal construction.

- Mid-20th Century: The introduction of hydraulic systems and improved concrete technology paved the way for more efficient and versatile slipform systems.

- Late 20th Century: The development of computer-controlled slipform systems further enhanced precision and accuracy.

- 21st Century: Continued advancements in automation, robotics, and material science are leading to even more sophisticated and sustainable slipform systems.

Key components of slipform system

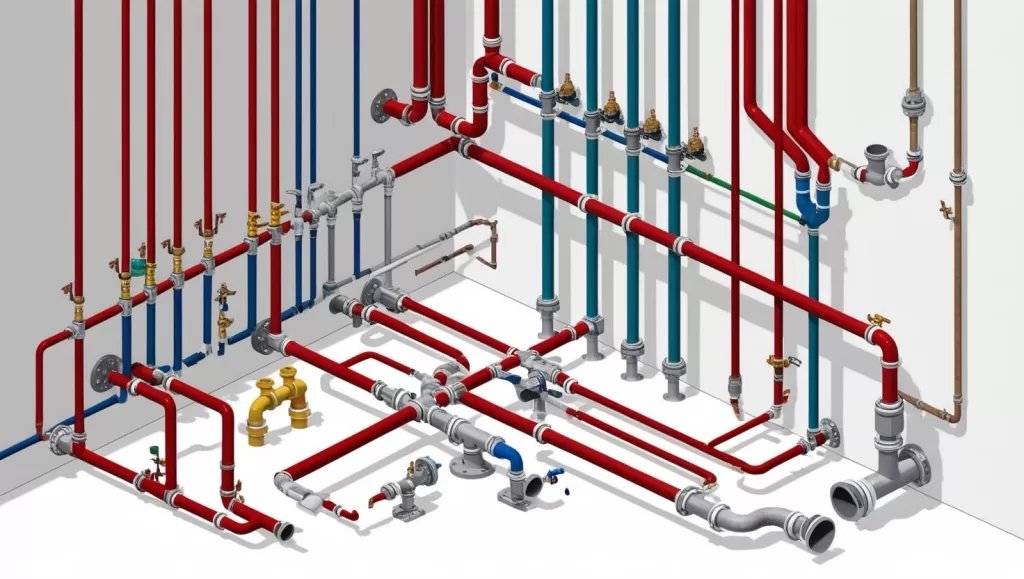

In slipform shuttering, several key components work together to facilitate continuous concrete construction:

- Formwork Panels: These vertical molds shape the concrete as it’s poured, ensuring the desired dimensions and surface finish. As the formwork ascends, the panels move upward at a controlled rate, allowing the structure to rise seamlessly.

- Jacking Systems: Hydraulic or pneumatic jacks lift the formwork incrementally. They support the formwork, platforms, crew, and withstand the hydrostatic pressure of the fresh concrete. The placement of jacks depends on vertical forces and lateral pressures, ensuring stability during the slipforming process.

- Working Platforms: These platforms provide safe and accessible areas for workers to perform tasks such as pouring concrete, monitoring alignment, and managing reinforcement. They move in tandem with the formwork, maintaining consistent working conditions.

- Support Structures: Elements like yokes and whalers distribute loads from the formwork and jacking systems, maintaining structural integrity. Yokes connect the formwork to the jacks, while whalers reinforce the formwork panels, ensuring even pressure distribution.

- Concrete Placement Equipment: Conveying systems like concrete pumps or chutes ensure continuous concrete delivery to the formwork.

- Vibration System: Compacts the concrete within the formwork, eliminating air pockets and ensuring a uniform density.

The cohesive interaction of these components enables the efficient construction of vertical structures. These structures are continuous and without joints. This process enhances both speed and structural integrity.

Types of slipform shuttering

Slipform shuttering encompasses several types, each tailored to specific construction needs. The most common types of slipform shuttering types are as follows

- Vertical slipform shuttering

- Horizontal Slipform shuttering

- Tapered slipform

- Conical slipform

- Egg shaped slipform

- Cantilever type

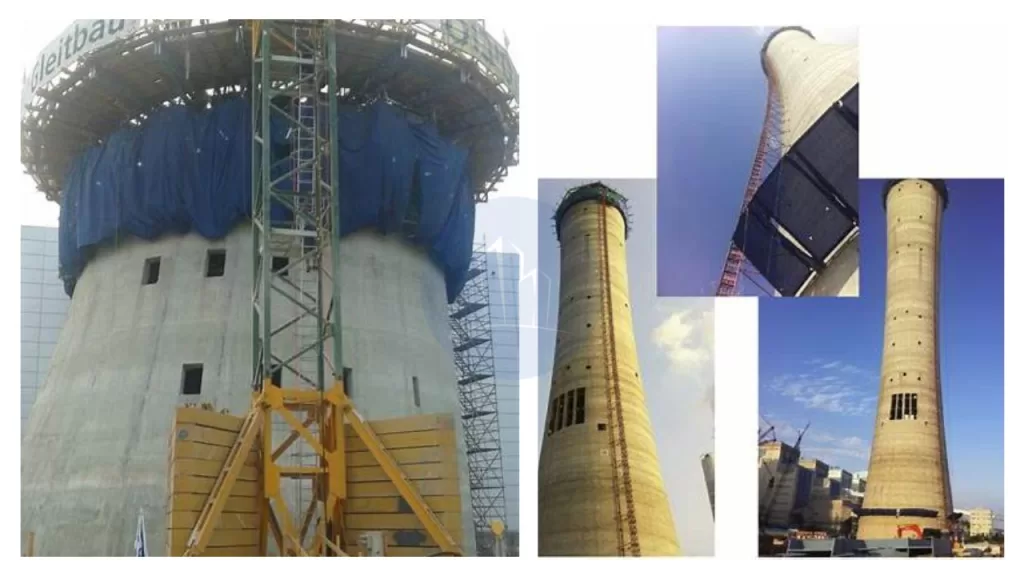

Vertical Slipform

Builders use vertical slipform to construct tall structures, such as silos, chimneys, or towers. They employ a moving formwork system that continuously ascends as they pour concrete. Workers gradually raise the formwork using hydraulic jacks, ensuring a smooth and consistent construction process.This method allows for the creation of vertical concrete structures without the need for scaffolding or traditional formwork systems. As the concrete sets, the formwork slips upwards, maintaining a uniform shape. Vertical slipform is efficient for projects requiring rapid construction, offering enhanced safety and reduced labor costs. It also ensures high-quality finishes and precise dimensions, making it suitable for large-scale industrial and infrastructure projects.

Horizontal Slipform shuttering

This technique is utilized in constructing horizontal structures such as road pavements and bridge decks. It allows the formwork to move horizontally. This movement enables continuous concrete placement along the structure’s length. Workers use horizontal slipform to create continuous concrete elements such as pavements, curbs, drainage channels, and safety barriers. This method involves the extrusion of concrete in situ, allowing for uninterrupted casting of long sections.

A specially designed machine has a mold with the required dimensions. It is equipped with vibrators for concrete compaction and moves forward at a controlled rate. The machine powers itself and mounts on wheels or tracks, ensuring stability during operation. As workers pour concrete from the rear of the machine, it becomes self-supporting. The machine follows a prefixed guide wire to achieve the correct line and level. This approach offers advantages such as speed, the ability to produce monolithic structures, and operational economy.

Tapered Slipform shuttering

This method is designed for structures with varying cross-sections, such as conical chimneys and cooling towers. It adjusts the formwork dimensions during the slipforming process. This adjustment achieves the desired tapering effect.

Builders use tapered slipform to create structures with a gradually narrowing shape. Examples include chimneys, cooling towers, and tall industrial structures. They employ movable formwork that adjusts in size as it rises, allowing for a tapered design. Similar to vertical slipform, workers pour concrete continuously as the formwork rises, typically using hydraulic jacks or other lifting mechanisms. Engineers design the formwork carefully to accommodate the structure’s changing cross-section, ensuring a precise and smooth taper.This method offers efficiency in construction, as it reduces the need for complex scaffolding and allows for a seamless, uniform finish. Tapered slipform is ideal for projects requiring strong, stable, and visually appealing tapered structures.

Conical Slipform shuttering

Builders use conical slipform to construct structures with a conical shape, such as cooling towers or silos. They use a moving formwork that continuously ascends as workers pour concrete. Workers shape the formwork to create a gradual narrowing toward the top. This process forms the cone. Workers raise the formwork using hydraulic jacks or other lifting mechanisms as the concrete cures, ensuring a smooth and consistent structure. This approach is highly efficient, as it eliminates the need for scaffolding and enables continuous, uninterrupted pouring. Conical slipform offers precise control over the shape and finish. It is ideal for large-scale, high-strength structures with conical geometry. It also reduces labor costs and construction time.

Egg-shaped Slipform

Engineers use egg-shaped slipform to create structures with an elliptical or egg-like shape. These structures include certain types of silos, industrial towers, and water or wastewater treatment facilities. They utilize specially designed formwork that moves vertically as workers pour concrete continuously. The formwork is shaped to create the unique, rounded profile of the egg shape, gradually narrowing at the top. Workers raise the formwork using hydraulic jacks or other lifting mechanisms, ensuring smooth and consistent construction. Egg-shaped slipform provides benefits like efficient construction with minimal labor, reduced material waste, and precise control over the shape. This technique is particularly suitable for structures requiring unique, aerodynamic designs, offering both functional and aesthetic advantages.

Cantilever Slipform

This method enables builders to construct structures that extend horizontally beyond their supports. These structures include certain bridge segments. It also allows them to build overhanging elements without the need for additional support scaffolding.

In cantilever slipform, construction teams use a method to build structures with an overhanging or projecting shape, such as bridges, dams, and tall towers. They gradually move the formwork system upwards while pouring concrete continuously. The structure itself supports the formwork, which extends outward as it rises, creating a cantilever effect. This technique is ideal for projects where workers have limited access to both sides of the structure or when constructing from the top down. Cantilever slipform ensures a precise and smooth finish, with high structural integrity. It reduces the need for scaffolding or external supports, making it an efficient and cost-effective method for large-scale projects that require overhanging sections or complex geometries.

Engineers design each type of slipform shuttering to meet specific architectural and structural demands, enhancing construction efficiency and quality.

Advantages of Slipform Formwork Construction

Slipform shuttering offers several advantages in construction, making it a preferred method for certain types of structures. Some key benefits include:

- Speed and Efficiency: Continuous pouring and raising of formwork allow for faster construction, reducing overall project timelines.

- Cost-Effective: It minimizes labor costs by eliminating the need for scaffolding and extensive formwork, resulting in a more economical process.

- High Quality: The method provides a smooth, consistent finish with high precision and uniformity in dimensions.

- Safety: With less reliance on manual labor and scaffolding, slipform offers enhanced safety for workers during construction.

- Minimal Material Wastage: The continuous nature of the process reduces material waste, making it more environmentally friendly.

- Reduced Need for Supervision: Automated or semi-automated systems reduce the need for constant supervision, leading to better management of resources.

- Versatility: Suitable for a variety of structures, including vertical, tapered, conical, and curved shapes, making it adaptable to different project requirements.

- Monolithic Structures: Slipform allows for the construction of monolithic concrete elements, improving the structural integrity of the finished project.

- Durability: The seamless construction process ensures strong, durable structures with fewer weak points.

- Reduced Labor Dependency: The method relies on machinery, reducing the need for large labor forces and improving construction consistency.

Challenges and disadvantages of Slipform Shuttering

While slipforming offers numerous advantages, it also presents several challenges that need to be carefully managed to ensure successful implementation.

- High Initial Setup Costs: The machinery, formwork, and equipment required for slipforming can be costly. This leads to high upfront investments. Such investments may not be feasible for smaller projects.

- Complexity in Design: Formwork design must be highly precise and adaptable to varying shapes and sizes. Skilled engineering and planning are necessary to meet specific project requirements.

- Skilled Labor: Skilled operators are crucial for proper alignment. They ensure smooth operation. The availability of experienced personnel is essential for effective slipforming.

- Concrete Quality Control: Maintaining consistency in concrete mix and quality is vital. Any variation in material quality, mix ratios, or curing methods can negatively impact the structure’s integrity.

- Weather Conditions: Unfavorable weather, such as heavy rain or freezing temperatures, can disrupt the slipforming process. It can also affect concrete curing. This necessitates careful planning and adjustments.

- Continuous Supervision: Despite automation, slipforming systems still require constant monitoring to address potential malfunctions or adjustments during the process.

- Site Access: Limited access to construction sites can make it challenging to transport the necessary machinery and materials.

By addressing these challenges with proper planning, slipforming can be an efficient construction method. Skilled labor and risk management also contribute to its effectiveness.

Applications of Slipform shuttering

Slipform shuttering is a versatile construction technique. It is employed across various industries for its efficiency. It also has the ability to create continuous, seamless structures. Key applications include:

- High-Rise Building Cores: Slipform is ideal for constructing the core walls of high-rise buildings. It enables rapid and uniform construction of elevator shafts and stairwells.

- Chimneys and Cooling Towers: The method is extensively used for building tall, tapered structures like chimneys and cooling towers. It ensures consistent quality and structural integrity.

- Silos and Tanks: Slipform facilitates the construction of large storage silos and tanks. It provides a cost-effective and efficient solution for industries requiring bulk storage.

- Bridges: Bridge piers and abutments benefit from slipform construction, allowing for continuous pouring and reducing the need for formwork stripping.

- Roadways and Pavements: In highway construction, slipform is used to build continuous pavements, curbs, and barriers. This technique enhances construction speed. It also improves surface uniformity.

- Dams: Slipform technology is applied in constructing concrete-faced dams, enabling efficient and continuous pouring of concrete.

- Water Towers: The technique is employed to construct the walls of water towers, ensuring uniformity and structural strength.

- Offshore Structures: Slipform is utilized in the construction of offshore platforms and structures, providing a robust and continuous concrete shell.

These applications highlight the versatility and efficiency of slipform shuttering in modern construction projects.

Advancements in slipform construction

Advancements in automation and real-time monitoring have significantly enhanced slipform shuttering processes. Integrating automated systems with real-time concrete monitoring allows for precise adjustments during construction, ensuring optimal curing conditions and structural integrity. By embedding sensors within the concrete, teams can monitor parameters like temperature and strength, enabling timely interventions and reducing delays.

Additionally, innovations in materials and formwork technology have improved efficiency and safety. Modern formwork systems are designed to be cost-effective, lightweight, reusable, and easy to assemble and dismantle. These advancements contribute to faster construction times and enhanced structural performance.

Collectively, these developments modernize construction practices by increasing efficiency, reducing costs, and ensuring higher-quality outcomes.

Conclusion

Slipform shuttering has revolutionized modern construction by enabling continuous, efficient, and precise building of complex structures. Its key benefits include faster construction timelines and reduced labor costs. It also minimizes material wastage and improves safety by eliminating the need for scaffolding. The method ensures a smooth, uniform finish. It is highly adaptable to various structural shapes. These include high-rise cores, chimneys, silos, cooling towers, bridges, and dams. It is particularly effective for projects requiring repetitive, large-scale concrete pouring. Slipform shuttering reduces manual labor. It optimizes resource use and modernizes construction practices. These improvements make construction practices more cost-effective, environmentally friendly, and precise. Its efficiency and scalability are crucial for meeting the demands of large infrastructure projects in today’s fast-paced construction industry.